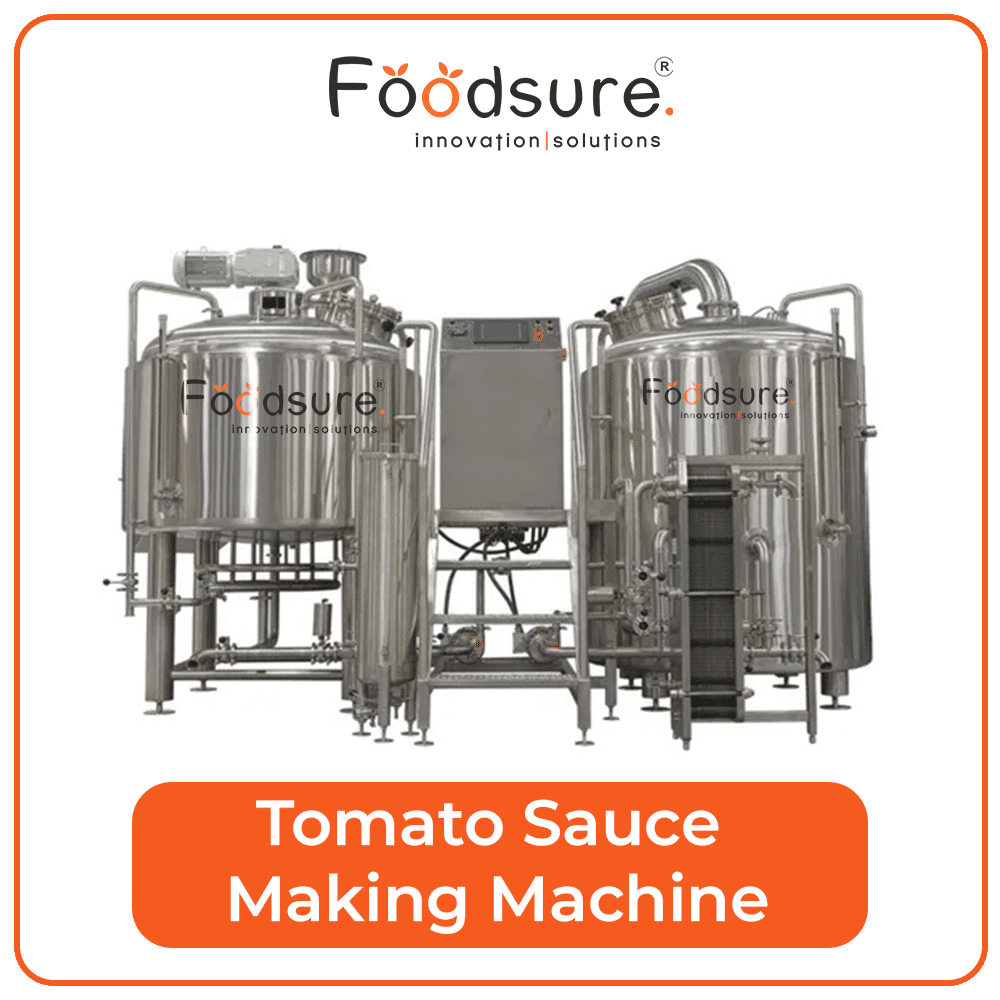

Sauce Plant

1000000 INR/Unit

Product Details:

- Product Type Sauces

- General Use Commercial, Industrial

- Material Stainless Steel

- Capacity upto 3000 Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

X

Sauce Plant Price And Quantity

- 1000000 INR/Unit

- 1000000.00 - 3000000.00 INR/Unit

- 1 Unit

Sauce Plant Product Specifications

- Yes

- Yes

- 20 kw Watt (w)

- 1000 Kilograms (kg)

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Stainless Steel

- Manual

- Sauces

- 1 year

- 440 V Watt (w)

- upto 3000 Kg/hr

- Table Top

- Commercial, Industrial

Sauce Plant Trade Information

- New Delhi

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging, Bubble Wrap Packaging

- All India

- ISO9001:2105

Product Description

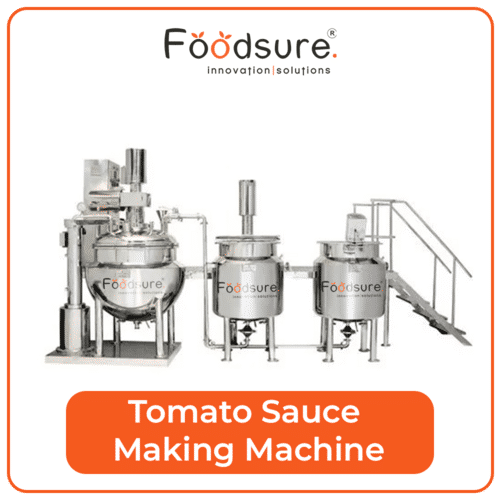

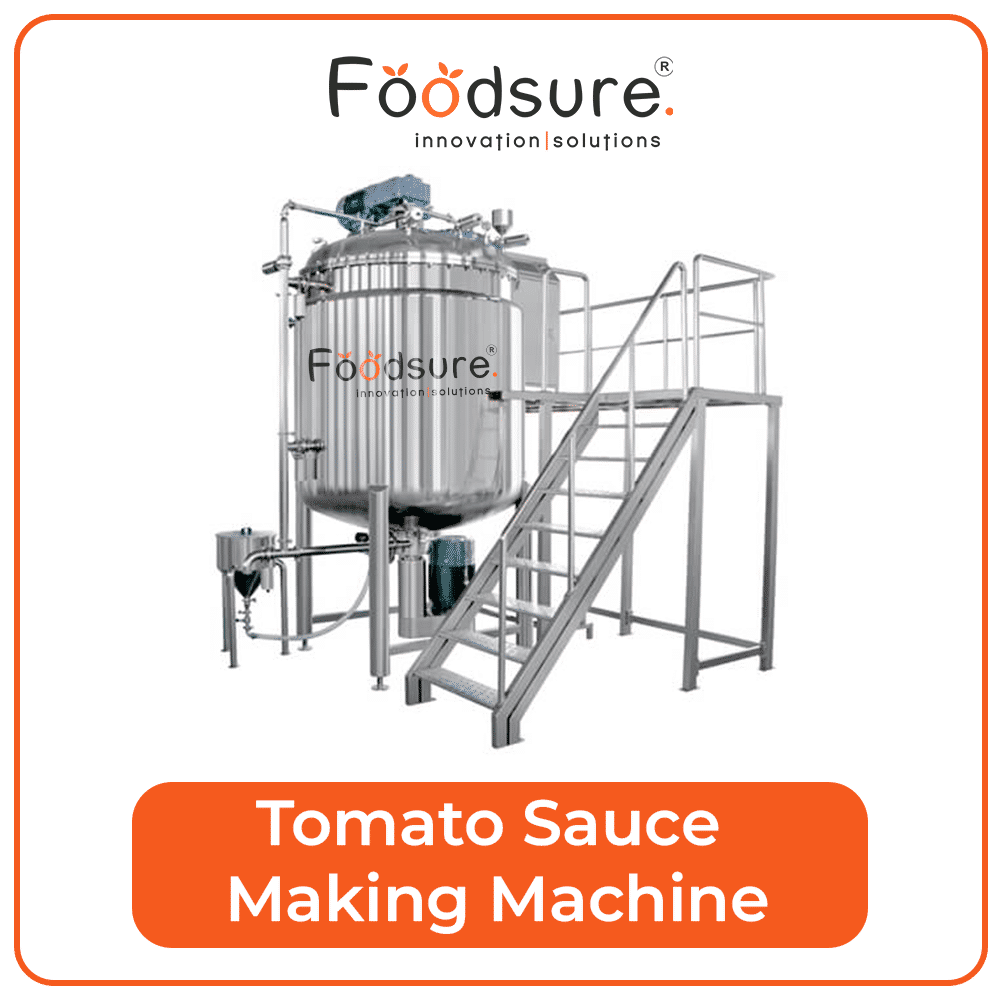

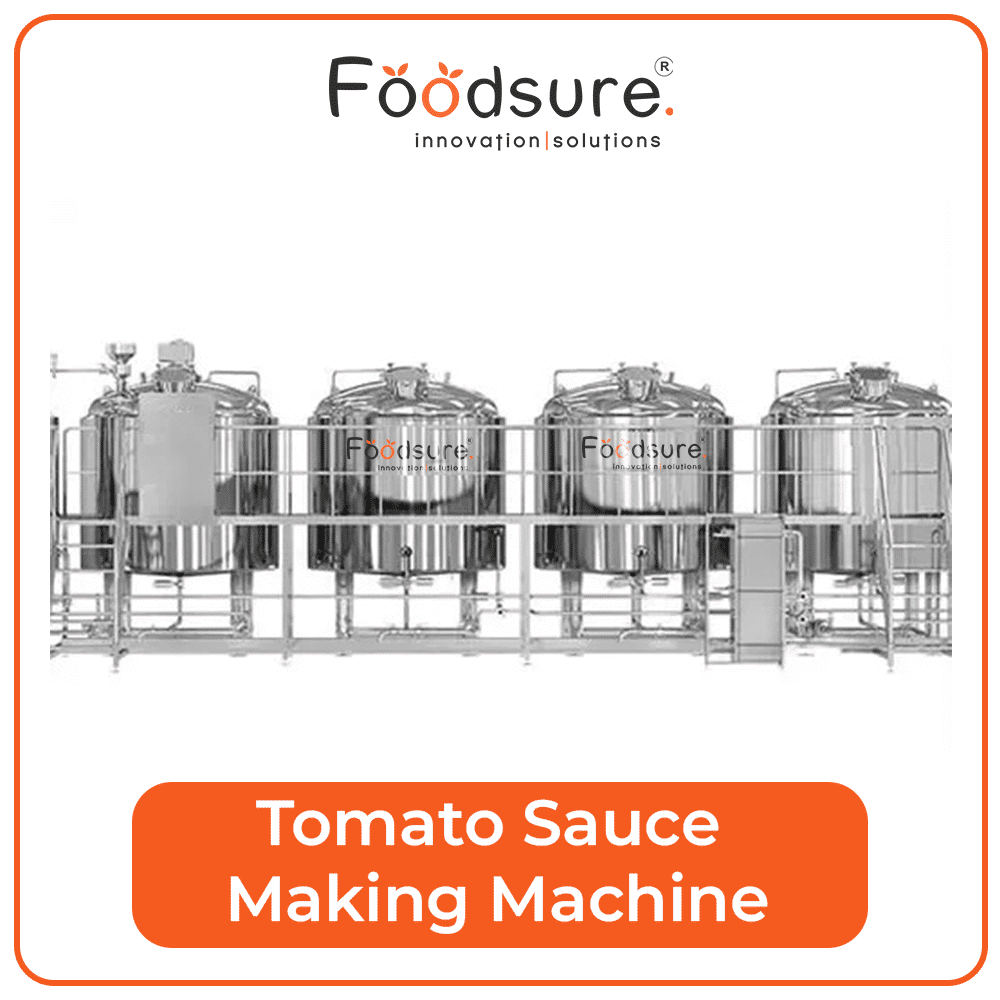

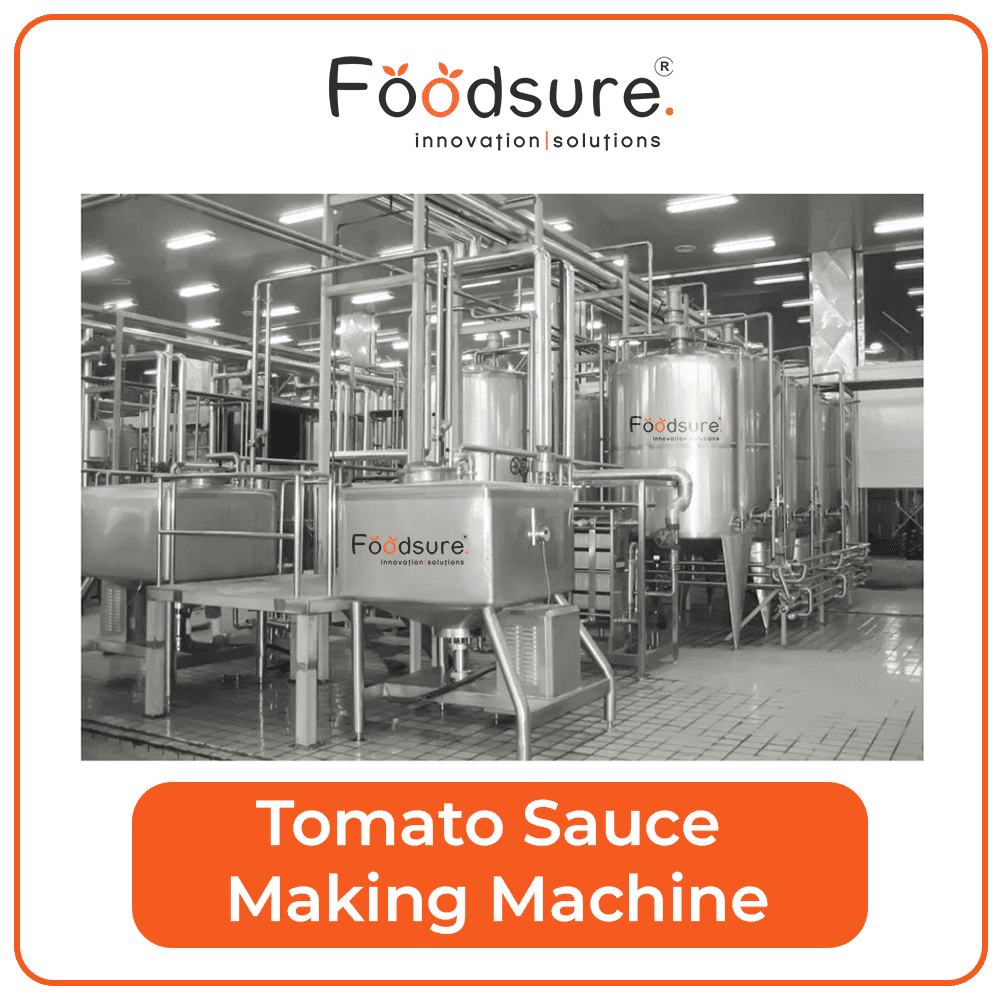

Foodsure sauce plant machines are meticulously designed and engineered to streamline the sauce production process, offering efficiency, reliability, and versatility. Our machines are equipped with state-of-the-art technology and innovative features to meet the diverse needs of sauce manufacturers.

At Foodsure, we offer a range of sauce plant machines tailored to different production requirements, including batch processing and continuous production lines. Our machines are capable of handling various types of sauces, including tomato-based sauces, pasta sauces, barbecue sauces, and more.

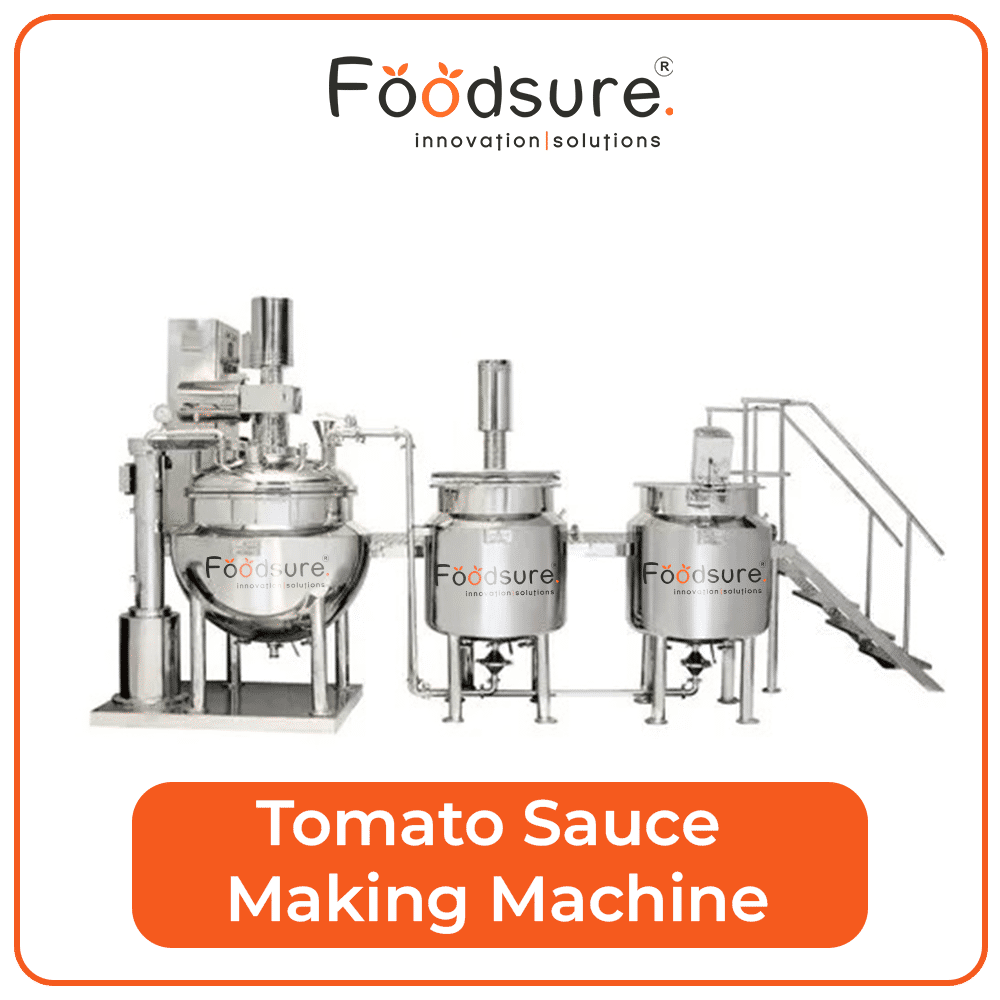

Key features of Foodsure sauce plant machines include:

- Precise Ingredient Handling: Our machines ensure precise ingredient dosing and mixing, allowing for consistent flavor profiles and product quality.

- High-Speed Mixing: With advanced mixing technology, our machines can efficiently blend ingredients to achieve the desired sauce consistency and texture.

- Automated Processes: Foodsure sauce plant machines are equipped with automated controls and processes, reducing manual intervention and ensuring efficient production.

- Customizable Configuration: We understand that sauce recipes vary widely, which is why our machines are customizable to accommodate different ingredients, viscosities, and production volumes.

- Hygienic Design: Our machines are designed with food safety and sanitation in mind, featuring stainless steel construction and smooth surfaces for easy cleaning and maintenance.

- User-Friendly Interface: Foodsures sauce plant machines are equipped with intuitive controls and interfaces, making them easy to operate and monitor for production personnel.

- Technical Support: We provide comprehensive technical support and assistance to ensure optimal performance of our sauce plant machines. Our team of experts is available to offer installation, training, troubleshooting, and ongoing maintenance services.

- With Foodsures sauce plant machines, manufacturers can enhance their production capabilities, improve efficiency, and maintain product quality consistency. Whether youre a small-scale producer or a large-scale manufacturer, our machines are designed to meet your specific needs and deliver exceptional results.

- Mixing Tank: Used for blending ingredients and creating homogeneous mixtures.

- Jacketed Kettle: Ideal for cooking and heating sauces, with a double-wall design for controlled temperature regulation.

- Homogenizer: Utilized to break down particles and ensure uniform texture and consistency in the sauce.

- Pump: Transfers the sauce between different processing stages, such as from the mixing tank to the filling machine.

- Filling Machine: Automatically dispenses the sauce into containers, such as bottles or jars, at a predetermined volume.

- Conveyor System: Transports containers between processing stages, ensuring a smooth and efficient production flow.

- Packaging Machine: Wraps, seals, and labels the containers filled with sauce for retail distribution.

- Pasteurizer: Heats the sauce to eliminate harmful bacteria and extend shelf life while preserving flavor and quality.

- Cooling Tunnel: Rapidly cools down packaged sauce to room temperature after pasteurization, preventing spoilage.

- Labeling Machine: Applies labels with product information, branding, and barcodes onto sauce containers.

- CIP (Clean-in-Place) System: Automates the cleaning process by circulating cleaning solutions throughout the equipment to maintain hygiene standards.

- Storage Tanks: Holds finished sauce products before packaging or distribution, ensuring a constant supply for orders.

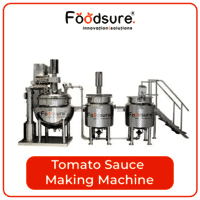

Advanced Automation & Efficiency

The Sauce Plants computerized system guarantees consistent production while enabling precise control with its manual override. Compact and table-top friendly, it fits seamlessly into commercial kitchens or industrial facilities, providing high output with minimal space requirements.

Eco-Conscious & Cost-Effective

Engineered for lower energy consumption, this plant minimizes operational costs while reducing environmental impact. Its quiet operation ensures a comfortable workspace, and its efficient design streamlines labor needs, optimizing productivity during large-scale manufacturing.

FAQs of Sauce Plant:

Q: How does the Sauce Plant automate the sauce production process?

A: The Sauce Plant uses a computerized system that manages key production stages, ensuring consistent quality and streamlined sauce preparation. Operators can adjust settings as needed via manual controls, catering to specific batch requirements.Q: What materials are used in constructing the Sauce Plant, and how does this impact durability?

A: The plant is built from premium stainless steel, which offers superior resistance to corrosion and wear, resulting in long-lasting and hygienic operationessential for commercial and industrial environments.Q: When is the best time to seek installation and setup for the Sauce Plant?

A: Installation is most effective during facility upgrades or when scaling up production. As a table-top machine, it can be integrated swiftly with minimal downtime and disruption to existing operations.Q: Where can this Sauce Plant be installed for optimal efficiency?

A: Its compact, table-top design allows installation in commercial kitchens, food manufacturing units, or centralized production facilities, maximising workflow and resource utilization.Q: What is involved in the sauce-making process using this machine?

A: The plant features automated mixing, cooking, and processing steps, managed by a computerized system but with manual control options to tweak recipes or batch sizes. This flexibility ensures consistent output and adaptable manufacturing.Q: How is the Sauce Plant typically used in commercial and industrial settings?

A: Businesses use it for large-scale sauce preparation, leveraging its high hourly capacity to meet the demands of restaurants, catering companies, and food processing industries efficiently and reliably.Q: What are the main benefits of choosing this Sauce Plant for production needs?

A: Key advantages include eco-friendly operation, low noise output, high efficiency, reduced energy consumption, and robust stainless steel construction. These features lead to lower operating costs, improved productivity, and reliable performance backed by a 1-year warranty.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

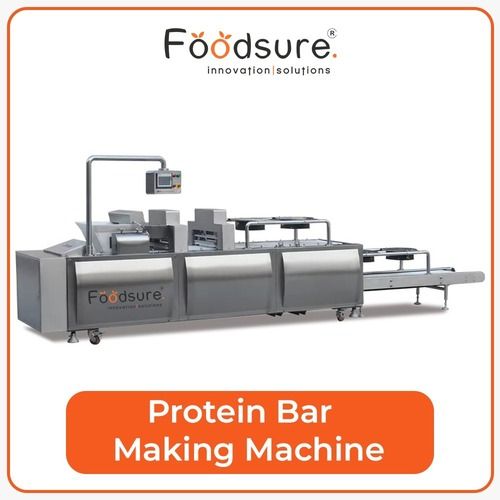

Other Products in 'Processing Machines' category

Back to top