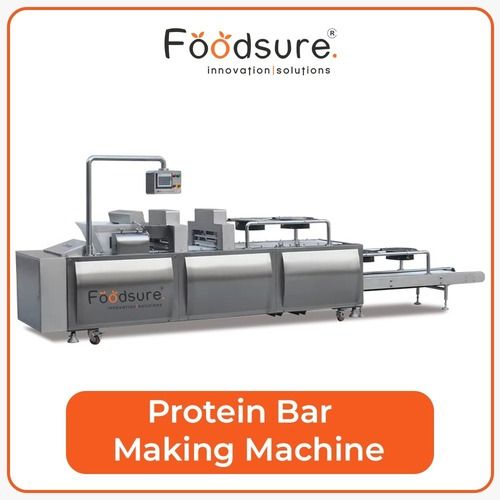

Protein Bar Machine

Product Details:

- Product Type Protein Bars, Energy Bar

- General Use Commercial, Industrial

- Material Stainless Steel

- Capacity Upto 1000 Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

Protein Bar Machine Price And Quantity

- 1 Unit

- 400000.00 INR/Unit

- 4000000.00 - 7000000.00 INR/Unit

Protein Bar Machine Product Specifications

- Table Top

- Commercial, Industrial

- Yes

- Protein Bars, Energy Bar

- Stainless Steel

- Manual

- 1000 Kilograms (kg)

- Yes

- 1 year

- 440 Watt (w)

- 20 Watt (w)

- Upto 1000 Kg/hr

Protein Bar Machine Trade Information

- New Delhi

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging, Bubble Wrap Packaging

- All India

- ISO9001:2015

Product Description

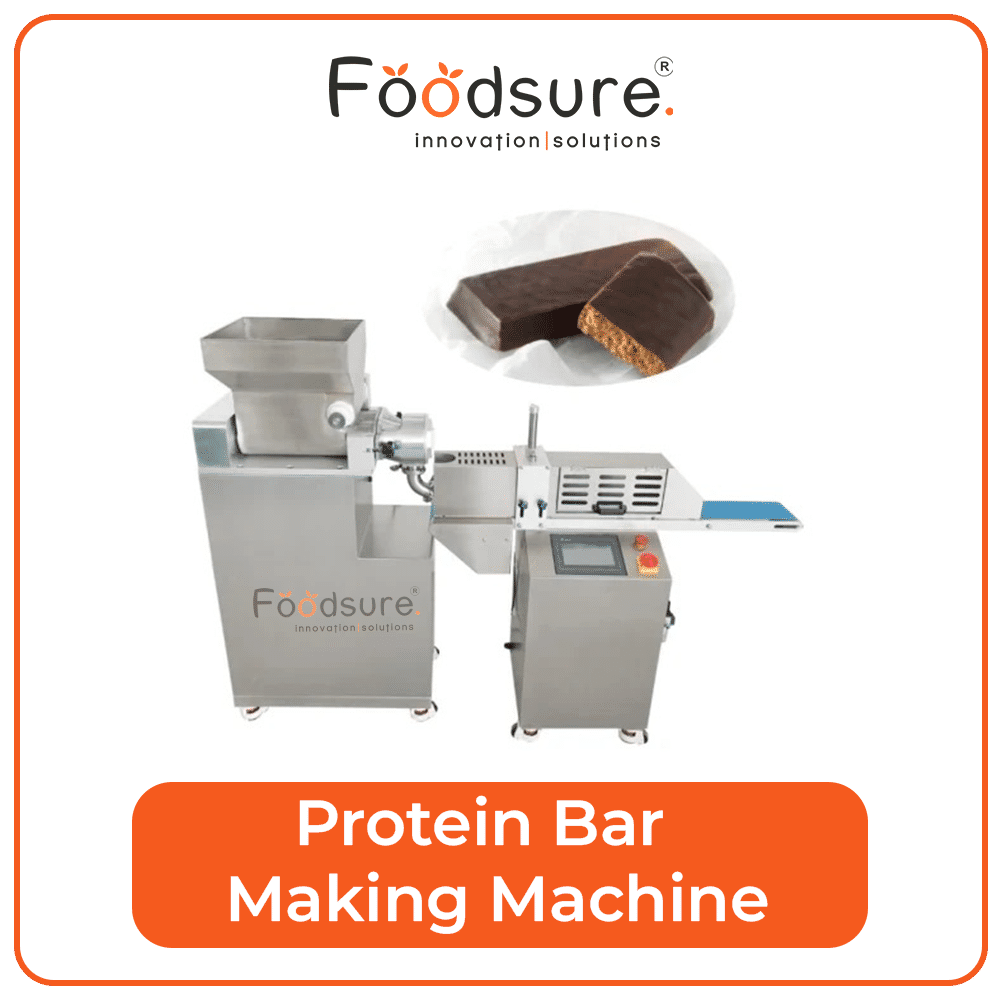

Protein Bar Machines

Upraise your protein bar production with Foodsure's latest Protein Bar Machines. Designed for perfect planning and consistency, these machines ease the entire process of making high-quality protein bars. No matter if you are holding a small business or a large-scale manufacturer. Our machines will help you produce delicious and nutritious protein bars smoothly.

Key Features:

Automatic Offering: Includes mixing, forming, cutting, and packaging.

High Order: Increases production speed while maintaining quality.

Better Results: Make sure accurate size and weight for every bar.

Human-friendly: It is easy to use for anyone, and simple to clean and maintain.

The Making Process: Protein Bar Machines

Firstly, the Protein Bar Machine includes a mixing process, it mixes various ingredients such as powders, nuts, and additional flavour to make the protein bar base. In this process, we use the best techniques and updated information to perfect the base and finishing texture. As soon as the ingredients are mixed, the protein bar mixture is used in a machine. This machine makes sure each bar has the same shape and size for further processing.

Next, the shaped protein bars go through a heating round. Here, they are heated carefully to set their texture and flavour. After this, include additional ingredients such as chocolate, yoghurt etc in your protein bars. After being coated, the protein bars are cooled in a special chamber to give a smooth finish. Then, the cooled bars are automatically packaged into individual wrappers or boxes, ready to be sold.

Experience ideal protein bar production with Foodsure's Protein Bar Machines. Boost your output and quality today! Buy from Foodsure for better results.

Please consider the environment before printing this email. Together, let's save trees and reduce paper waste for a greener tomorrow.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+