Mayonnaise Machine Manufacturer in Jammu and Kashmir

Product Details:

- Features User-Friendly Interface, Easy Cleaning

- Feeding System Automatic

- Function Type Mixing, Emulsifying

- Heating Method Electric Heating

- Operating Temperature Up to 120C

- Speed Mode Variable

- Power Source Electric

- Click to View more

Mayonnaise Machine Manufacturer in Jammu and Kashmir Price And Quantity

- 1 Unit

- 1500000 INR/Unit

Mayonnaise Machine Manufacturer in Jammu and Kashmir Product Specifications

- Fixed

- SS304/SS316

- Mayonnaise Manufacturing Machine

- Three Phase

- Batch Type

- Low

- Automatic

- 50/60 Hz

- 100-1000 kg/hr

- Mixing and Emulsifying Machine

- Rectangular

- Electric

- 220-380 V

- Variable

- Up to 120C

- Electric Heating

- Industrial Mayonnaise Production

- Silver

- Automatic

- Mixing, Emulsifying

- Yes

- Yes

- PLC Control

- High Efficiency, Rust Proof

- 3000 x 1000 x 1600 mm

- 5 kW

- 800 kg

- Stainless Steel

- User-Friendly Interface, Easy Cleaning

Product Description

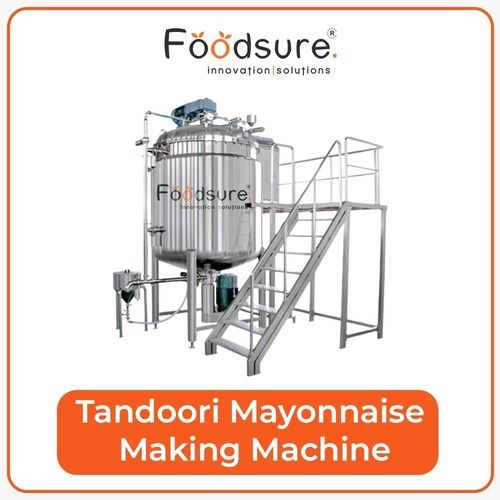

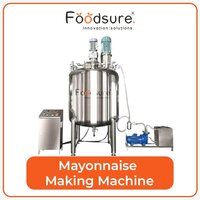

Mayonnaise-making machine in Jammu and Kashmir

Foodsure offers perfect mayonnaise plant solutions that are created to make the production process simple and easy. Also, make sure to give the highest quality results to its clients. Our mayonnaise plants provide them with unique and the best machinery and technology to easily process and package mayonnaise products. Processes include, from emulsification to pasteurization and packaging, our plants manage every stage of the production process with clarity and stability. We serve clients from all around the corners. Clients from every state of the country and some international parts can get the advantages of mayonnaise-making machines by Foodsure in the easiest way.

We believe in food safety and thus, we properly follow quality control rates to make sure that our mayonnaise products match the highest industry norms. Our mayonnaise plants are perfectly made to different production capacities and product variations. Whether you're producing traditional mayonnaise, flavored variants, or speciality formulations, our plants can be created to suit your major requirements. We have some great success stories that provide our clients with the best mayonnaise machines from almost every state of the country.

With Foodsure's Mayonnaise plant solutions, you can expect:

- Systematic Production: Our plants are made for perfect efficiency, allowing you to increase productivity and reduce lots of hard efforts in production work.

- Quality Standards: We maintain quality control rates throughout production to make sure that every step matches your quality standards.

- Flexibility: Our plants are flexible to make changes in production requirements, allowing you to scale up or down as needed.

- Current Technology Trends: We use the latest technology and innovation to set up the plant's performance and improve product quality.

- Team of Experts: Our team of skilled professionals provides complete support, from the beginning of plant design to installation, training, and other maintenance.

Join hands with us, achieve your targets, and take your mayonnaise production to a high level with ease in effort.

A mayonnaise machine is a creative equipment used for mixing, emulsifying & packaging large quantities of mayonnaise. These machines are mainly used in food production processes like for factories or commercial units.

Fully functional machines are made specifically for mixing and emulsifying ingredients in mayonnaise, while others are made for mixing and packaging. The most common mixing method is to mix oil, vinegar, lemon juice and other ingredients in a large bowl or container.

Some machines that can be used in the mayonnaise process are described below:

- High-shear mixers: High-shear mixers are the central part of the mayonnaise production process. These mixers are made to easily mix the oil and egg yolk mixture, making the perfect mixture.

- Emulsifier Machines: Equipment Emulsifier Homogenizers are important in getting the thickness and texture of mayonnaise.

- Filling Equipment: Once the mayonnaise is ready, it needs to be packaged for distribution. After this purpose, packaging and bottling have a major role to play.

- Labeling Machine: This machine is used to attach labels to containers or bottles.

- Capping Machine: It is a machine used for closing. Close the jar or bottle filled with mayonnaise.

- Packing Machine: A machine used to pack containers and fill cans or bottles of mayonnaise into cartons or boxes for shipping.

If you are seeking the best mayonnaise-making machines, no matter where you are living we make these machines possible for you. Get the best from Foodsure.

Advanced Mixing and Emulsifying Technology

Equipped with a high shear homogenizer and an electric heating system, the machine ensures thorough mixing and emulsification of mayonnaise. Variable speed settings (200-1500 RPM) allow flexibility for diverse recipes. Its efficient process enhances texture and stability in large-scale production.

Intuitive and Modern Control Panel

The digital touch screen interface and PLC control provide simplified operation, enabling easy parameter adjustment and process monitoring. User-friendly design reduces training time and helps operators maximize productivity while ensuring safety with overload protection.

Effortless Maintenance and Hygiene

Built for easy cleaning, the integrated CIP (Clean in Place) system streamlines maintenance routines. High-quality stainless steel construction prevents rust, while bottom discharge valve design ensures smooth product outflow and easy residue removal, supporting strict hygiene standards.

FAQ's of Mayonnaise Machine Manufacturer in Jammu and Kashmir:

Q: How does the mayonnaise machine ensure consistent product quality during mixing and emulsification?

A: The machine employs a high shear homogenizer capable of operating between 200-1500 RPM with adjustable speed settings. This flexibility allows precise control over the mixing and emulsifying process, promoting uniform mayonnaise texture and stability for batch production.Q: What industries can benefit from installing this mayonnaise mixing and emulsifying machine?

A: This machine is ideal for the food and beverage sector, dairy industries, and commercial kitchens that require efficient, large-volume mayonnaise production with consistent quality and easy operation.Q: When is it necessary to use the Clean in Place (CIP) system, and how does it work?

A: The CIP system should be used after every batch or change of product to maintain hygiene. It enables automated, thorough cleaning of internal surfaces using standard industrial water supply, reducing downtime and manual labor.Q: Where should the mayonnaise machine be installed for optimal performance?

A: It should be installed in an industrial setting with fixed installation, access to three-phase electric supply (220-380 V), standard water connections, and adequate ventilation, as per the machine's dimensions (3000 x 1000 x 1600 mm).Q: What is the process for starting and operating the machine?

A: Operators begin by loading ingredients via the automatic feeding system, initiating the process through the digital touch screen interface. Set desired mixing speed, temperature (up to 120C), and start the emulsifying cycle. Monitor and adjust parameters using the PLC system until the batch is complete.Q: How does the bottom discharge valve benefit the user during operation?

A: The bottom discharge valve allows efficient and easy emptying of the finished product, minimizing waste and ensuring quick turnaround for subsequent batches while maintaining hygiene.Q: What are the key advantages of this mayonnaise machine over traditional mixers?

A: It offers automatic operation, computerized controls, rapid cleaning with the CIP system, and high-efficiency mixing and emulsification. The user-friendly interface, overload protection, rust-proof stainless steel construction, and low noise levels further enhance safety and convenience for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+