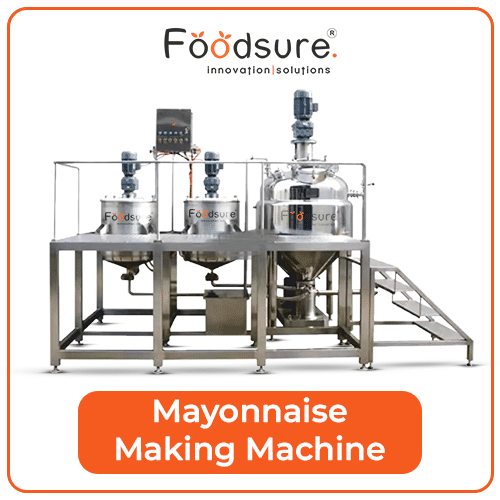

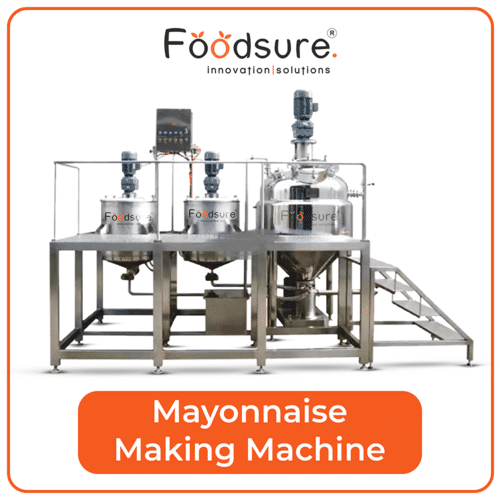

High Quality Mayonnaise Making Machine

Product Details:

- Product Type Automatic

- General Use Industrial & Commercial

- Material Stainless Steel

- Capacity Upto 3000 kg per HRS Kg/hr

- Weight (kg) 20000 Kilograms (kg)

- Product Shape Other

- Computerized Yes

- Click to View more

High Quality Mayonnaise Making Machine Price And Quantity

- 1000000.00 INR/Unit

- 1 Unit

- 500000.00 - 2000000.00 INR/Unit

High Quality Mayonnaise Making Machine Product Specifications

- 440 Watt (w)

- Yes

- Other

- Manual

- Table Top

- Upto 3000 kg per HRS Kg/hr

- Other

- Automatic

- Stainless Steel

- 20 Watt (w)

- 20000 Kilograms (kg)

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Industrial & Commercial

- Yes

- 1 Year

High Quality Mayonnaise Making Machine Trade Information

- New Delhi

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging, Shrink Wrap, Bubble Wrap

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001:2015

Product Description

Mayonnaise machines are specialized equipment used to mix, emulsify, and package mayonnaise in large quantities. These machines are typically used in industrial food production settings, such as factories or commercial kitchens, where high volumes of mayonnaise need to be produced efficiently.

Mayonnaise machines can vary in size and complexity, from small tabletop models to large, fully automated systems. Some machines are designed specifically for mixing and emulsifying the ingredients in mayonnaise, while others are designed for both mixing and packaging.

The mixing process typically involves combining oil, vinegar or lemon juice, and other ingredients in a large mixing bowl or tank. The ingredients are then blended together using high-speed rotating blades or paddles until a smooth and creamy emulsion is formed.

Once the mayonnaise is mixed, it can be pumped into packaging containers, such as jars or squeeze bottles, using filling machines. These machines can be manual or fully automated, depending on the volume of production and the level of precision required.

Overall, mayonnaise machines play a crucial role in streamlining the production of mayonnaise in large-scale food production settings. They help to ensure consistency and efficiency in the mixing and packaging process, while also reducing labor costs and improving food safety standards. As an AI language model, I do not have access to the most current market reports, as they are not available in my training data.

Mayonnaise is a popular condiment that is widely used in various food applications. According to a report by Research and Markets, the global mayonnaise market was valued at $10.6 billion in 2020 and is expected to grow at a CAGR of 4.2% from 2021 to 2028.

The growth of the mayonnaise market is driven by factors such as the increasing demand for convenience foods, changing consumer preferences for different flavors and textures, and the growing popularity of plant-based mayonnaise products. However, factors such as health concerns related to the high-fat content of mayonnaise and the availability of alternative condiments such as salsa, ketchup, and mustard could limit the growth of the market.

Overall, the mayonnaise market is expected to continue growing in the coming years, driven by the increasing demand for convenience foods and the introduction of new flavors and formulations to cater to changing consumer preferences. Here are some of the machines that may be used in the mayonnaise production process.

- Mixing Tank:A large tank used to mix the ingredients of the mayonnaise. It may have a motorized mixer or agitator to ensure even mixing.

- Emulsifying Machine:A specialized machine used to emulsify the mixture of oil, vinegar or lemon juice, and other ingredients into a smooth and creamy mayonnaise.

- Homogenizer:A machine used to break down the fat particles in the mayonnaise to create a smooth and consistent texture.

- Filling Machine:A machine used to fill jars, bottles, or other containers with mayonnaise. It may be a manual or automated machine, depending on the volume of production.

- Labeling Machine:A machine used to apply labels to the filled jars or bottles of mayonnaise.Capping Machine: A machine used to apply caps or lids to the filled jars or bottles of mayonnaise.

- Packaging Machine:A machine used to package the filled and labeled jars or bottles of mayonnaise into boxes or cases for shipment.

Overall, the use of these machines helps to streamline the mayonnaise production process, improve efficiency, and maintain consistency in the quality of the final product.

Choosing Foodsure for a mayonnaise making machine can be a strategic decision for several reasons:

- Expertise in Food Processing:Foodsure specializes in food processing equipment and technology. They have expertise in designing, manufacturing, and implementing machinery tailored to the needs of the food industry, including mayonnaise production.

- Customization:Foodsure can customize mayonnaise making machines to suit your specific production requirements. Whether you need a small-scale batch production system or a large-scale automated production line, Foodsure can tailor the machine to meet your needs.

- Quality and Reliability:Foodsure is known for the quality and reliability of its equipment. Their machines are built to industry standards using high-quality materials and components, ensuring durability and consistent performance.

- Efficiency and Productivity:Foodsure's mayonnaise making machines are designed for efficiency and productivity, helping you streamline your production process and increase output while maintaining quality standards.

- Innovation and Technology:Foodsure continuously invests in research and development to incorporate the latest innovations and technologies into their equipment. This ensures that you have access to state-of-the-art machinery that optimizes performance and maximizes efficiency.

- Compliance and Safety:Foodsure ensures that its equipment complies with relevant safety and regulatory standards. They prioritize safety features and design elements to minimize risks and ensure a safe working environment for your staff.

- Technical Support and Service:Foodsure provides comprehensive technical support and service to help you install, operate, and maintain your mayonnaise making machine. Their team of experts is available to assist with troubleshooting, repairs, and maintenance to minimize downtime and maximize uptime.

- Cost-effectiveness:Foodsure offers competitive pricing for its machinery, providing excellent value for your investment. Their machines are designed for long-term reliability and performance, helping you achieve a strong return on investment over time.

Overall, choosing Foodsure for your mayonnaise making machine ensures that you have a reliable partner with the expertise, technology, and support needed to optimize your production process and meet your business goals effectively.

In the Indian market, there are several types of mayonnaise available, catering to different consumer preferences and dietary requirements. Some common types include:

- Regular Mayonnaise:This is the traditional mayonnaise made with egg yolks, oil, vinegar or lemon juice, and seasonings. It has a rich and creamy texture and is used in a variety of dishes such as sandwiches, salads, and dips.

- Eggless or Vegan Mayonnaise:Eggless or vegan mayonnaise is made without eggs, often using ingredients like plant-based oils, soy milk, and vinegar or lemon juice. It's suitable for vegans and those with egg allergies or dietary restrictions.

- Low-Fat or Light Mayonnaise:Low-fat or light mayonnaise contains less fat and fewer calories compared to regular mayonnaise. It's often made with reduced-fat oils or thickeners to achieve a lighter consistency while maintaining flavor.

- Flavored Mayonnaise:Flavored mayonnaise comes in various flavors such as garlic, chili, mustard, or herb-infused varieties. These add an extra dimension of taste to dishes and are popular for enhancing sandwiches, wraps, and salads.

- Diet Mayonnaise:Diet mayonnaise is formulated to be lower in calories and fat, making it suitable for those following a weight-loss or calorie-conscious diet. It may contain artificial sweeteners or other additives to reduce calorie content.

Regarding Foodsure machines for mayonnaise production in the Indian market, it would depend on the specific requirements of your production process, scale of operation, and budget. Foodsure is known for its expertise in food processing equipment and can provide customized solutions tailored to your needs. Here are some factors to consider:

- Capacity:Ensure that the machine's capacity aligns with your production requirements. Foodsure can provide machines suitable for small-scale artisanal production as well as large-scale industrial production.

- Customization:Foodsure can customize machines to meet your specific requirements, whether it's for traditional mayonnaise production or specialized varieties like eggless or flavored mayonnaise.

- Quality and Reliability:Foodsure machines are known for their quality construction and reliable performance. They are built to industry standards using high-quality materials and components, ensuring durability and long-term operation.

- Technical Support and Service:Consider Foodsure's after-sales support and service offerings, including installation, training, maintenance, and troubleshooting. Ensure that you have access to timely support to minimize downtime and maximize productivity.

- Cost-effectiveness:Evaluate the cost-effectiveness of Foodsure machines in terms of upfront investment, operational costs, and return on investment. Compare the features, performance, and pricing of Foodsure machines with other options in the market to make an informed decision.

Overall, Foodsure machines can be a viable option for mayonnaise production in the Indian market, provided they meet your specific requirements and offer the performance, reliability, and support you need for your business.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+