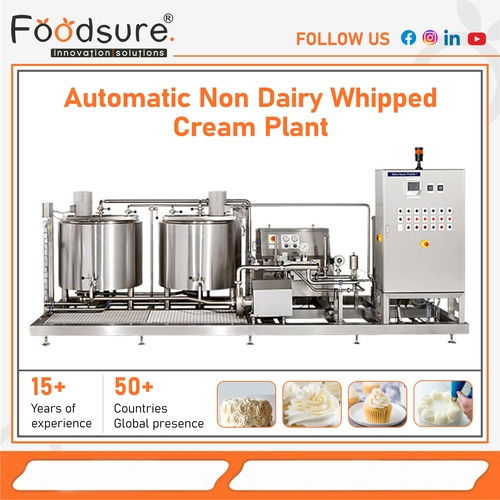

Non Dairy Whipped Cream Plant

Product Details:

- Product Type Non- Dairy Whip Cream

- General Use Industrial and Commercial

- Material Stainless Steel

- Capacity Upto 3000 kg Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

Non Dairy Whipped Cream Plant Price And Quantity

- 850000.00 - 1000000.00 INR/Piece

- 8000000.00 INR/Piece

- 1 Unit

Non Dairy Whipped Cream Plant Product Specifications

- Industrial and Commercial

- Stainless Steel

- 1 Year

- Upto 3000 kg Kg/hr

- Yes

- Non- Dairy Whip Cream

- Table Top

- 420 Watt (w)

- Yes

- 1000 Kilograms (kg)

- 20 Watt (w)

- Manual

Non Dairy Whipped Cream Plant Trade Information

- New Delhi

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 30 Week

- Free samples are available

- Wooden Packaging , Bubble Wrap Packaging

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001:2015

Product Description

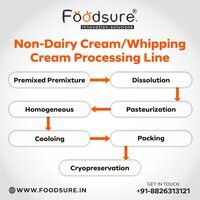

Non-dairy whipped cream can be made in a factory using a variety of processes, but here is a general overview of the process:

-

Ingredients:The first step is to gather all the ingredients needed to make non-dairy whipped cream. This typically includes a non-dairy cream base (such as coconut cream or soy cream), sweeteners, stabilizers (such as carrageenan or xanthan gum), and any desired flavors or colors.

-

Mixing:The non-dairy cream base is typically mixed with the sweeteners and stabilizers in a large mixing tank. This mixture is then homogenized to ensure a smooth and consistent texture.

-

Pasteurization:The mixture is then pasteurized to ensure food safety and extend the shelf life of the product.

-

Chilling: The mixture is chilled to a specific temperature to ensure that it will whip properly.

-

Whipping:The chilled mixture is then whipped in a high-speed mixer to incorporate air and create a light, fluffy texture. The whipped cream is then dispensed into containers, such as aerosol cans or plastic tubs.

-

Packaging:The containers are then labeled and packaged for distribution to stores or foodservice outlets.

TYPES-

-

Coconut whipped cream:Coconut whipped cream is made from the cream that rises to the top of a can of coconut milk. It can be whipped like traditional cream and has a slightly sweet coconut flavor.

-

Soy whipped cream: Soy whipped cream is made from soy milk and is similar in texture to dairy-based whipped cream. It has a neutral flavor, which makes it versatile for use in various recipes

-

Rice whipped cream:Rice whipped cream is made from rice milk and is a good alternative for people who are allergic to soy or nuts. It has a slightly sweet flavor and is lighter in texture than dairy-based whipped cream.

-

Almond whipped cream:Almond whipped cream is made from almond milk and has a nutty flavor. It is a good alternative for people who are allergic to dairy, soy, or gluten.

-

Cashew whipped cream:Cashew whipped cream is made from cashew cream and has a rich, creamy texture. It is a good alternative for people who are allergic to dairy or soy.

-

-

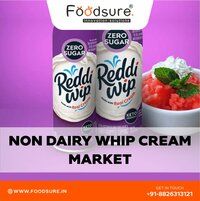

The non-dairy whipped cream market has experienced significant growth in recent years due to the increasing demand for plant-based alternatives to traditional dairy products. According to a report by Grand View Research, the global non-dairy whipped cream market size was valued at USD 585.5 million in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 11.2% from 2021 to 2028.

Some of the leading companies in the non-dairy whipped cream market include:

-

-

According to a report by Market Research Future (MRFR), the global non-dairy whipped cream market size was valued at USD 580.1 million in 2020 and is expected to reach USD 933.3 million by 2027, growing at a compound annual growth rate (CAGR) of 7.3% during the forecast period from 2021 to 2027.

The report cites several factors driving the growth of the non-dairy whipped cream market, including increasing demand for plant-based alternatives to traditional dairy products, rising health consciousness among consumers, and growing vegan and lactose-free food trends.

Based on the source, the report segments the non-dairy whipped cream market into soy-based, coconut-based, and others (including almond, rice, and oat-based).

The ingredients used in non-dairy whipped creame.

-

Plant-based milk,Sweetener,Stabilizers,Emulsifiers,Flavorings,Acids,

High-Yield Non Dairy Whipped Cream Production

Engineered for heavy-duty use, the plant delivers consistent quality non-dairy whipped cream for a range of industrial and commercial needs. The automatic system streamlines mixing, whipping, and dispensing, while its robust build enables continuous operation, maximizing productivity and minimizing downtime.

Efficient and User-Friendly Operation

Featuring a manual control system with computerized functionality, the machine offers precision and flexibility during production. Its table-top installation facilitates easy access and maintenance, ensuring operators can manage output efficiently and adapt to specific processing requirements.

FAQs of Non Dairy Whipped Cream Plant:

Q: How is the Non Dairy Whipped Cream Plant installed at my facility?

A: The plant is designed for table-top installation, making it simple to set up in industrial and commercial environments. Professional installation services are available to ensure proper integration and safe commissioning.Q: What materials are used in the construction of the whipped cream plant?

A: The plant is constructed from high-grade stainless steel, which provides durability, hygiene, and resistance to corrosion, making it suitable for heavy-duty food processing applications.Q: When does the warranty begin, and what does it cover?

A: The one-year warranty begins from the date of installation and covers manufacturing defects and mechanical issues, ensuring peace of mind for your operation.Q: Where is service and technical support available for this plant in India?

A: Comprehensive service and technical support are provided across India, including installation, maintenance, and troubleshooting by our dedicated team of service providers.Q: What is the process for producing non-dairy whipped cream in this plant?

A: Automatic and computerized workflows manage mixing, whipping, and dispensing, achieving up to 3,000 kg per hour. Operators can use manual controls to adjust parameters as needed, ensuring optimal texture and consistency.Q: How is the machine used for industrial and commercial purposes?

A: Ideal for bakeries, food processing units, and large catering operations, the plant produces high volumes of non-dairy whipped cream efficiently and reliably, meeting demands for both industrial and commercial enterprises.Q: What benefits do users gain from this whipped cream plant?

A: Users benefit from significant time and labor savings, superior quality control, large output capacity, and a durable, easy-to-maintain system that enhances overall operational productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+