Granola Bar Plant setup

Product Details:

- Product Type Granola Bar

- General Use Industrial and Commercial

- Material Stainless Steel

- Capacity upto 500 kg Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

Granola Bar Plant setup Price And Quantity

- 1 Unit

- 650000.00 INR/Unit

Granola Bar Plant setup Product Specifications

- 20 Watt (w)

- Granola Bar

- Yes

- Industrial and Commercial

- 420 Watt (w)

- Table Top

- upto 500 kg Kg/hr

- Manual

- 1 Year

- Stainless Steel

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Yes

- 1000 Kilograms (kg)

Granola Bar Plant setup Trade Information

- New Delhi

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 7 Days

- Yes

- Free samples are available

- Wooden Packaging, Bubble Wrap Packaging

- All India

- ISO9001:2015

Product Description

Let delve into the fascinating world of Granola Bar Manufacturing and explore the essential aspects of setting up a granola bar production plant.

What Are Granola Bars?

Granola bars are compact and portable sources of nutrition, typically composed of an assortment of ingredients such as oats, nuts, honey, dried fruit, and sometimes chocolate. Let break down the key components:

- Oats: Oats serve as the primary component in granola bars. They are rich in dietary fiber, contributing to heart health.

- Nuts: Nuts provide plant-based protein and monounsaturated fats, which are beneficial for overall health.

- Honey: Honey acts as a natural sweetener and binder in granola bars.

- Dried Fruits: Dried fruits offer a concentrated source of vitamins and fiber.

- Chocolate (Optional): Some granola bars include chocolate or other sweet extras, enhancing taste and consumer appeal.

Evolution of Granola Bar Production

Over the years, granola bar production has evolved significantly due to technological advancements and changing consumer preferences. Here how it has transformed:

Manual Process (Early Stages):Initially, granola bars were manually mixed and shaped before baking.This process was labor-intensive and inconsistent.

Automation Revolution:

- Automation transformed the production process.

- Modern granola bar production lines feature:

- Precision ingredient batching systems

- Mixing machines for uniform blending

- Forming machines to shape bars

- Baking ovens for ideal texture

- Cooling conveyors to lower bar temperature before packaging

Healthier Options:

The shift toward healthier, organic, and allergen-free bars led to new production processes and stringent quality controls.

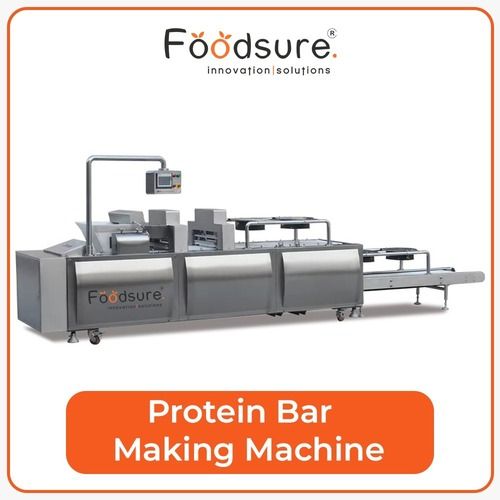

Critical Machines in Granola Bar Manufacturing:

- Ingredient Batching Systems: These precision machines measure ingredients accurately for each batch, ensuring consistency in taste and nutrition.

- Mixing Machines: Ingredients are thoroughly blended to achieve uniform distribution.

- Forming Machines: These machines press the mixture into the desired bar shape and size.

- Baking Ovens: Bars are baked to achieve the ideal texture and consistency.

- Cooling Conveyors: After baking, bars cool down gradually before packaging

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+