Garlic Paste Machine

Product Details:

- Product Type Garlic Paste Machine

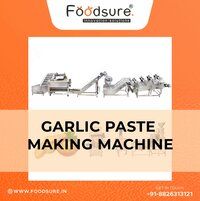

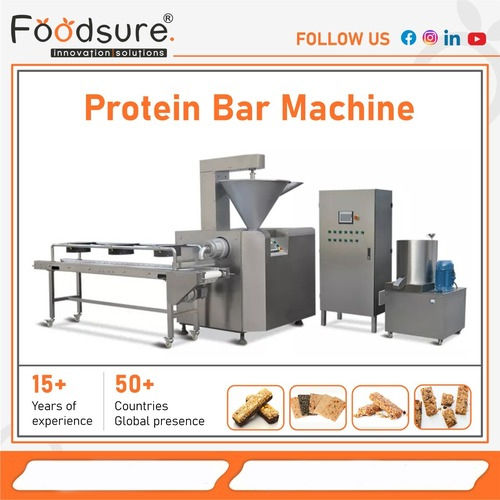

- General Use Commercial, Industrial

- Material Stainless Steel

- Capacity upto 1000 kg Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

Garlic Paste Machine Price And Quantity

- 1000000.00 INR/Unit

- 1 Unit

Garlic Paste Machine Product Specifications

- upto 1000 kg Kg/hr

- 1 year

- Commercial, Industrial

- Stainless Steel

- 440 V Volt (v)

- Table Top

- 20 kw Watt (w)

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Yes

- Yes

- PLC Control

- Garlic Paste Machine

- 1000 Kilograms (kg)

- White

Garlic Paste Machine Trade Information

- Mundra

- Paypal Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015

Product Description

Garlic Sauce Making Machine Production Factory

Garlic Sauce Making Machine Production Equipment - Garlic sauce production consists of many steps & often requires the use of special machines to make the process work . Below is a description of the main steps & types of machinery commonly used in garlic plants :

Care & Processing Mix : Garlic must be cleaned & sorted before serving . This step will include machines such as washing machines , dryers , & individual machines .

peeling machine : Garlic peeling machine is used to remove the peel of garlic cloves . There are many types of peelers , dry & wet , that use water to facilitate the peeling process .

Chop : After the garlic cloves are peeled , they are usually chopped . Chop or grind for greater convenience . Machines such as garlic crushers or choppers can be used for this purpose .

Grinder or Milling Machine : Garlic paste is usually made by grinding or grinding garlic . This step is usually done using a grinder or stone grinder equipped with a sharp blade .

Mixing & mixing : After grinding , the garlic paste needs to be mixed or stirred to thicken . This can be done using a mixer or blender .

Homogenization : A homogenizer can be used to ensure the garlic paste has a uniform texture & size This step is very important to obtain & mix the correct product .

Pasteurisation or Sterilisation : Pasteurisation or sterilisation is necessary to extend the shelf life of garlic paste . This can be done by heat treatment or by cooking using a pasteurizer .

Collection & Packaging : The final step is to collect the garlic medicine in the package for packaging & shipping . At this stage , automatic filling & packaging machines such as capping machines & labelling machines are frequently used .

Quality Control : Quality control throughout the entire production process ensures the consistency , taste & safety of your fish . marinara These include sensors , cameras & clocks .

Conveyor System : The conveyor system plays an important role in transporting onions to different stages of the production line , ensuring that the process is continuous & works well .

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+