Welcome to Foodsure!

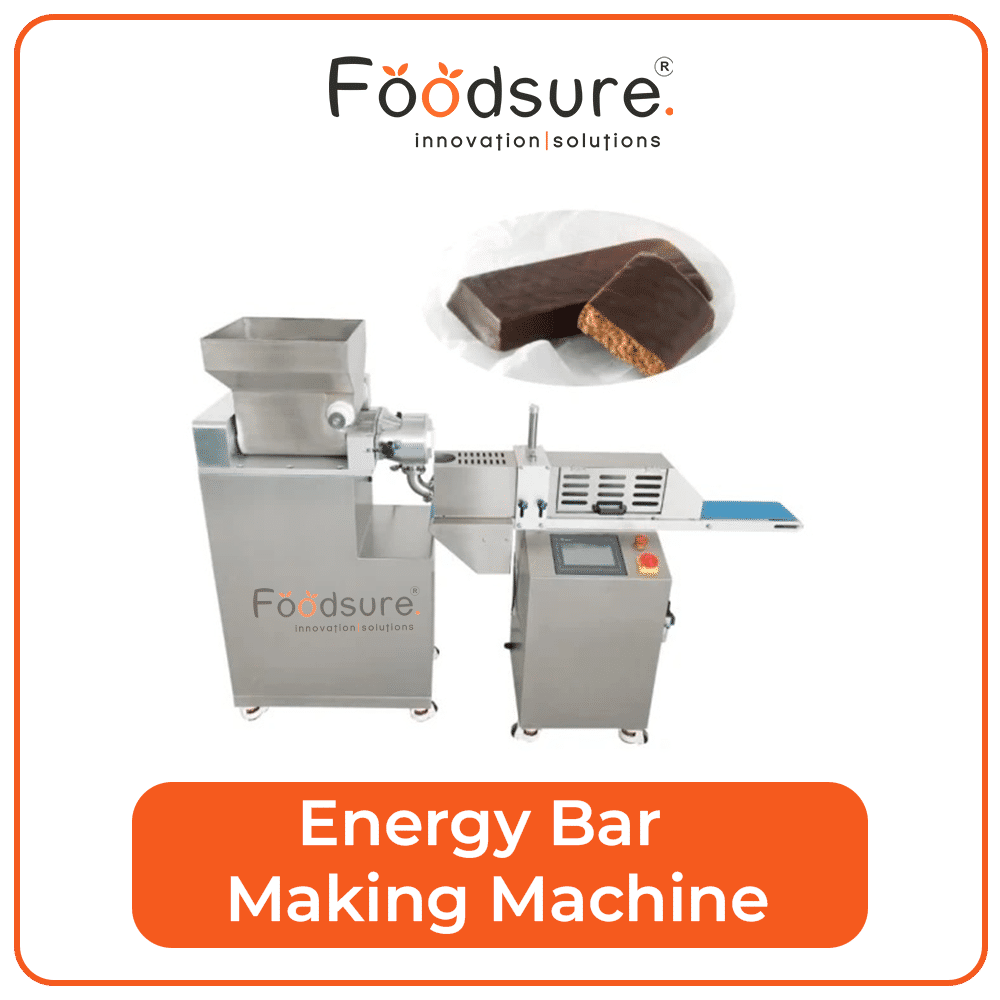

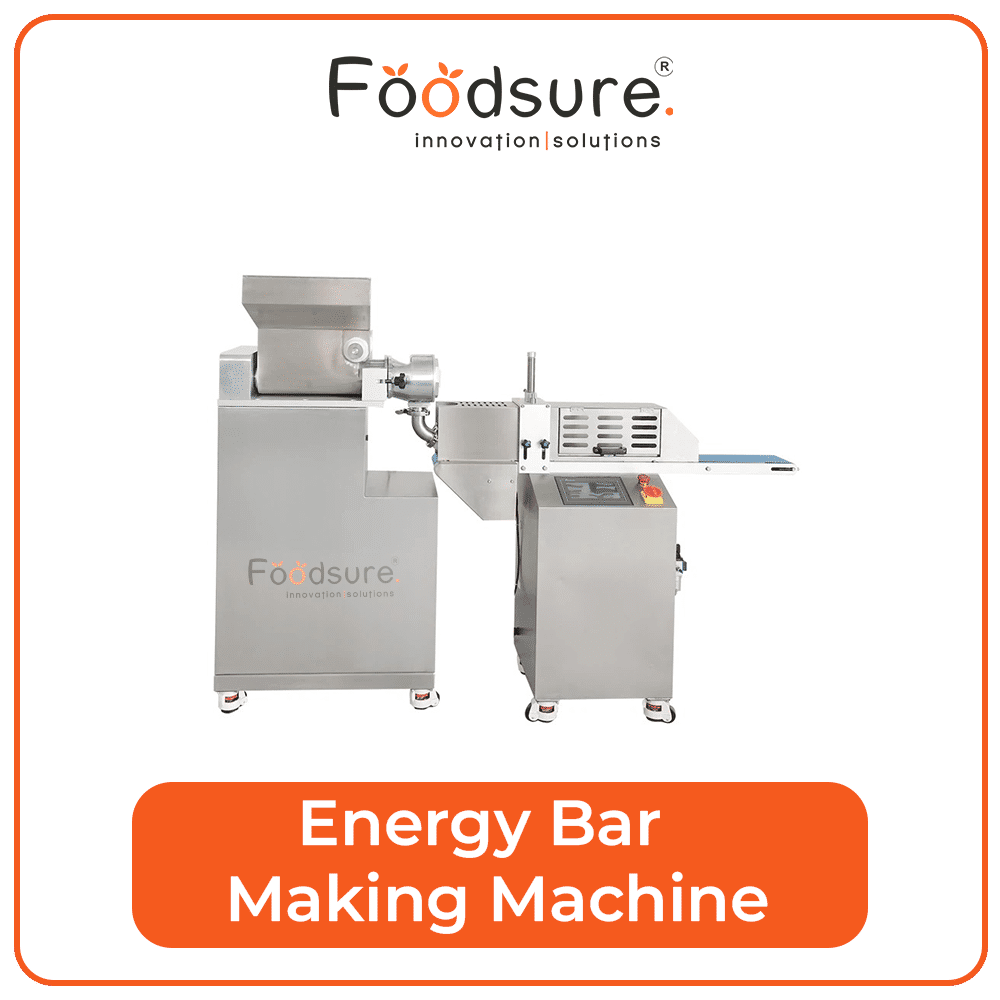

Energy Bar Machine

4000000 INR/Unit

Product Details:

- Product Type Energy Bar

- General Use Commercial, Industrial

- Material Stainless Steel

- Capacity upto 1000 kg Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

X

Energy Bar Machine Price And Quantity

- 4000000 INR/Unit

- 4000000.00 - 7000000.00 INR/Unit

- 1 Unit

Energy Bar Machine Product Specifications

- upto 1000 kg Kg/hr

- 1000 Kilograms (kg)

- 440 Watt (w)

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Commercial, Industrial

- Yes

- 1 year

- Manual

- Energy Bar

- Table Top

- 20 Watt (w)

- Yes

- Stainless Steel

Energy Bar Machine Trade Information

- New Delhi

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging, Bubble Wrap Packaging

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001:2015

Product Description

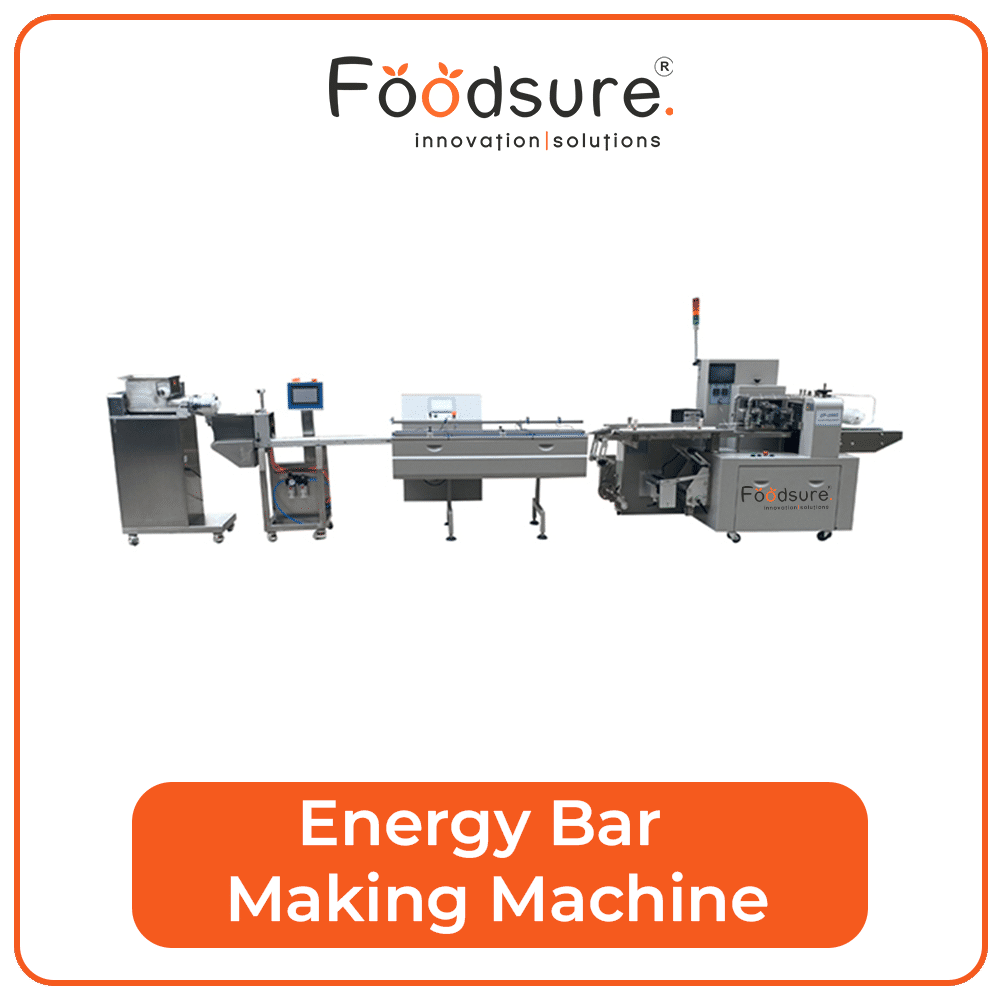

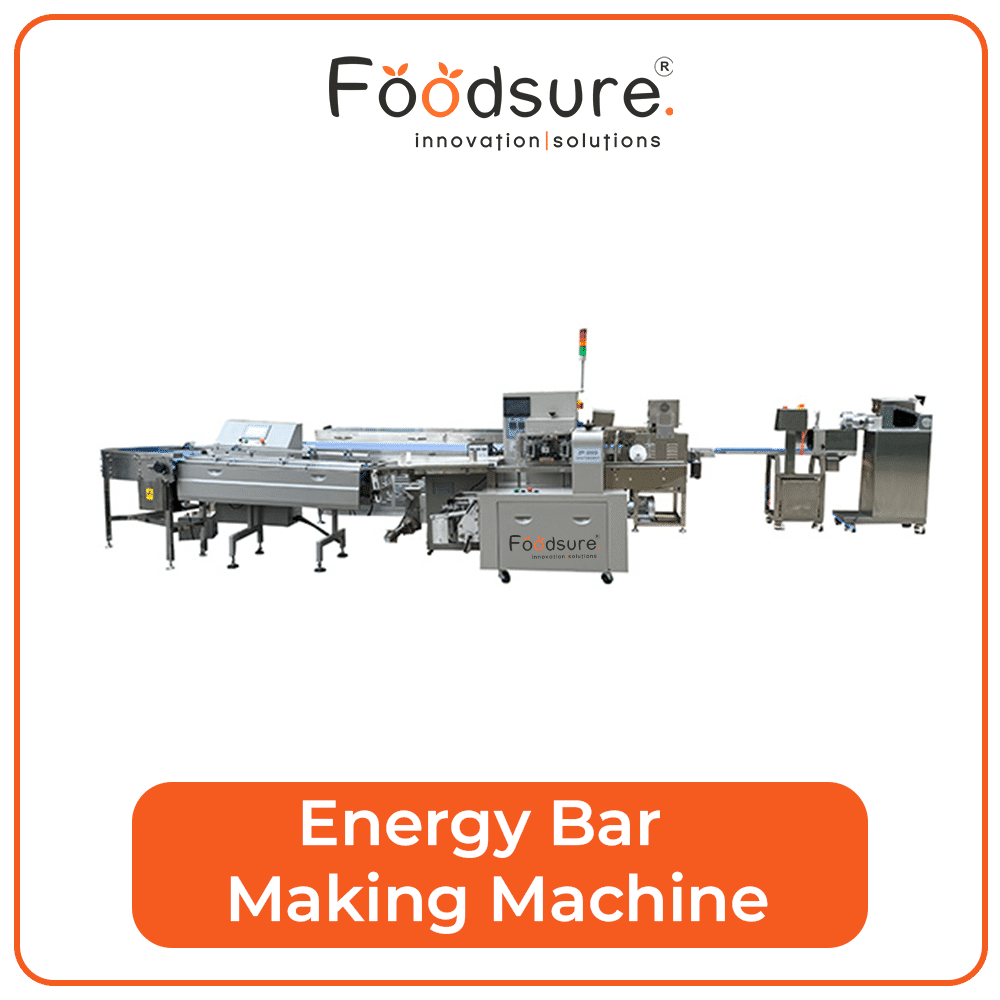

The Foodsure Energy Bar Machine is a cutting-edge solution designed to streamline the production of energy bars with precision and efficiency. This comprehensive system integrates various units and components to automate the manufacturing process and ensure consistent quality across batches.- Mixing and Blending Unit: This unit is equipped with advanced mixing technology to combine ingredients such as oats, nuts, seeds, dried fruits, sweeteners, and flavorings. It ensures thorough blending and uniform distribution of ingredients to create the energy bar base.

- Extrusion System: The extrusion system shapes the mixed ingredients into the desired form of energy bars. It offers precise control over the size, shape, and texture of the bars, allowing for customization according to product specifications.

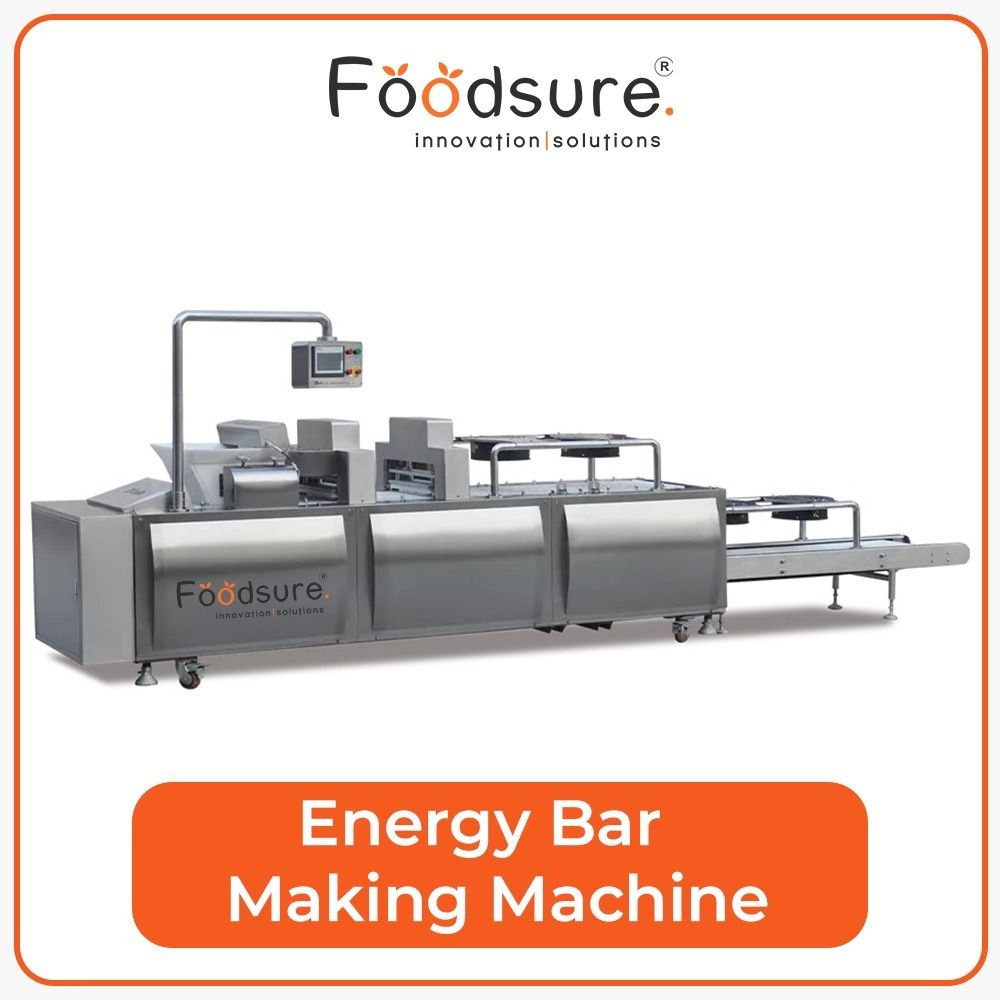

- Heating and Curing Chamber: The energy bars pass through this chamber for controlled heating to set the texture and flavor. It ensures proper cooking and consistency while enhancing the taste and aroma of the bars.

- Coating and Topping Unit: This unit applies coatings such as chocolate, yogurt, or other flavorings to the energy bars for added taste and visual appeal. It also adds toppings such as nuts, seeds, or dried fruits for texture and decoration.

- Cooling and Packaging System: After coating, the energy bars are cooled to room temperature in a dedicated chamber to ensure proper setting of the coatings. Once cooled, they are automatically packaged into individual wrappers or boxes for distribution and sale.

- Controls and Monitoring Systems: The Energy Bar Machine is equipped with advanced controls and monitoring systems to ensure smooth operation and consistent product quality. These systems provide real-time data and allow for easy adjustments during production to maintain optimal performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Processing Machines' category

Back to top