Welcome to Foodsure!

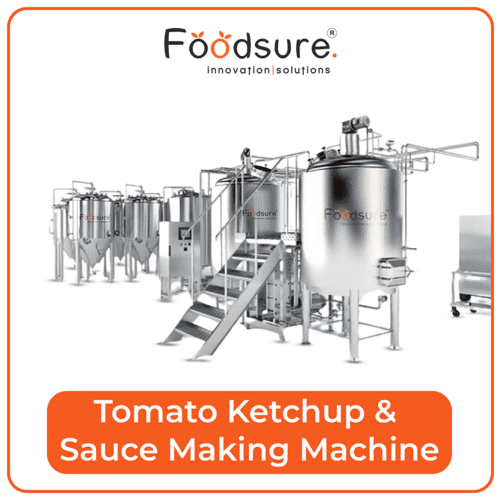

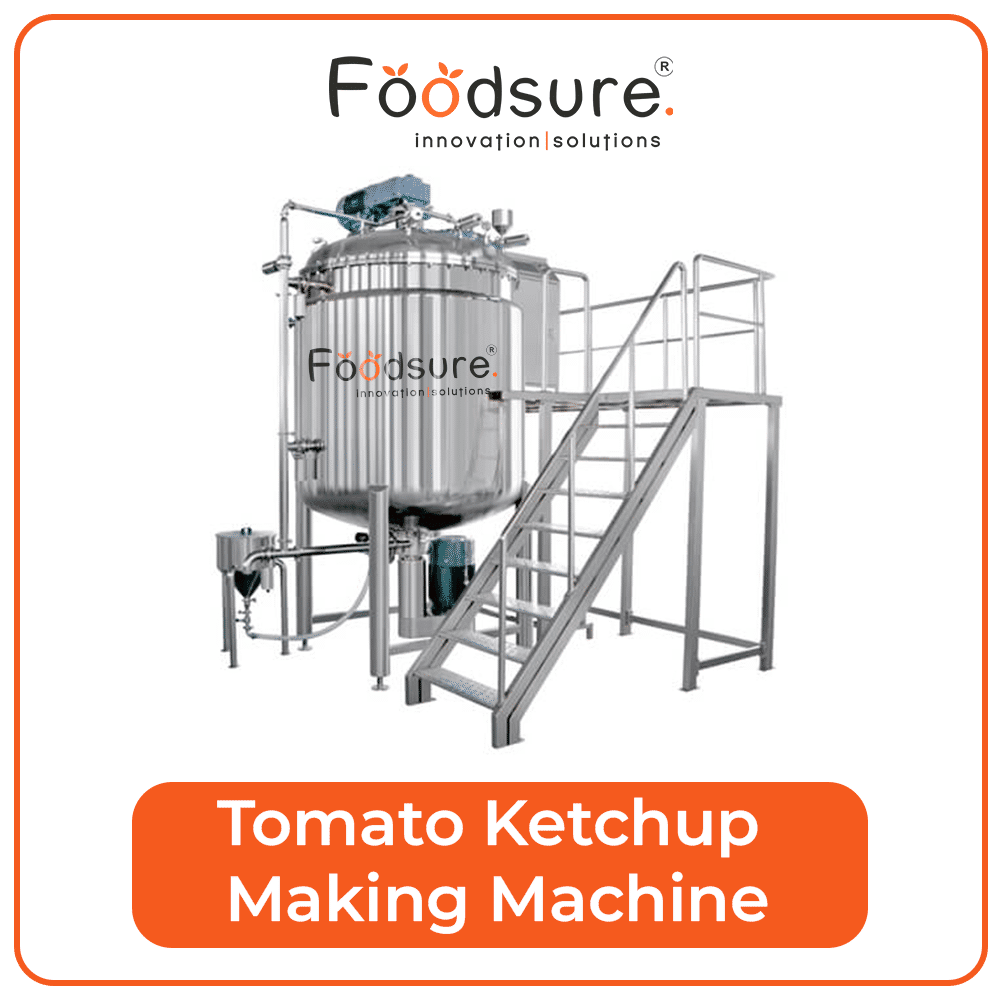

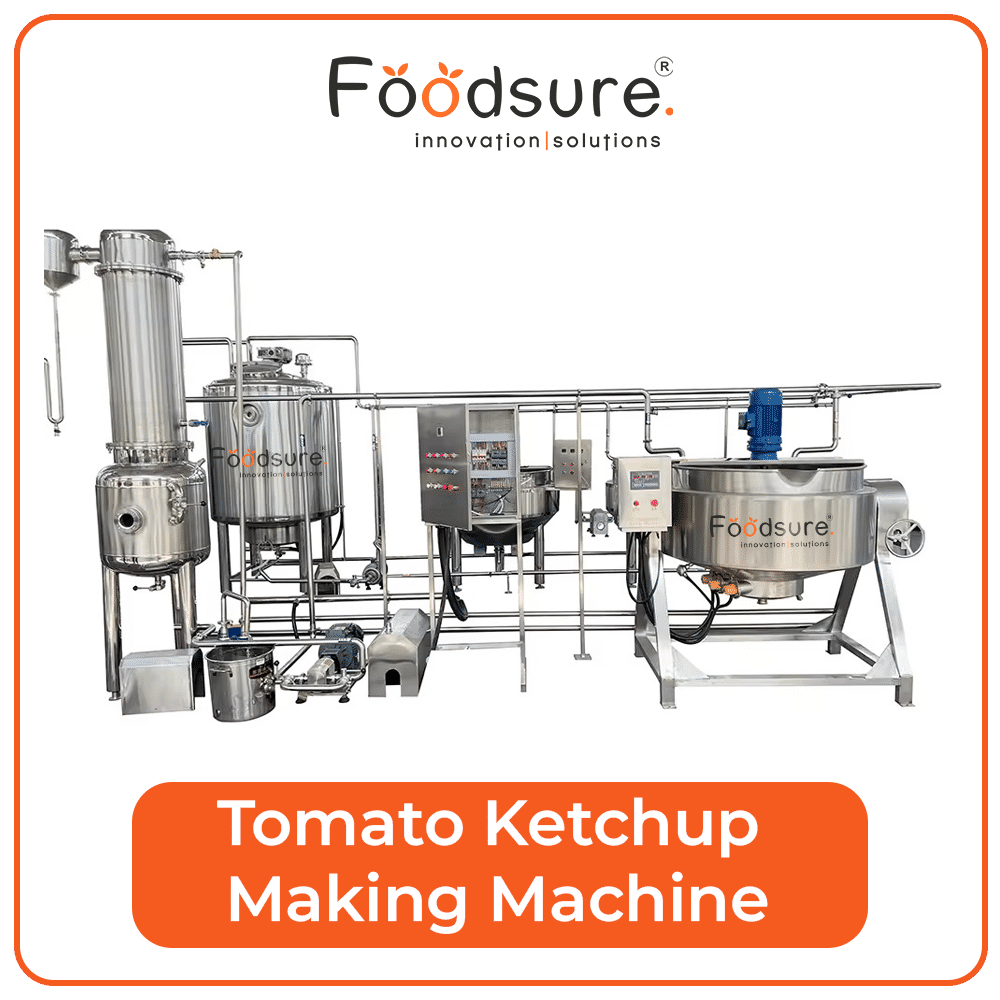

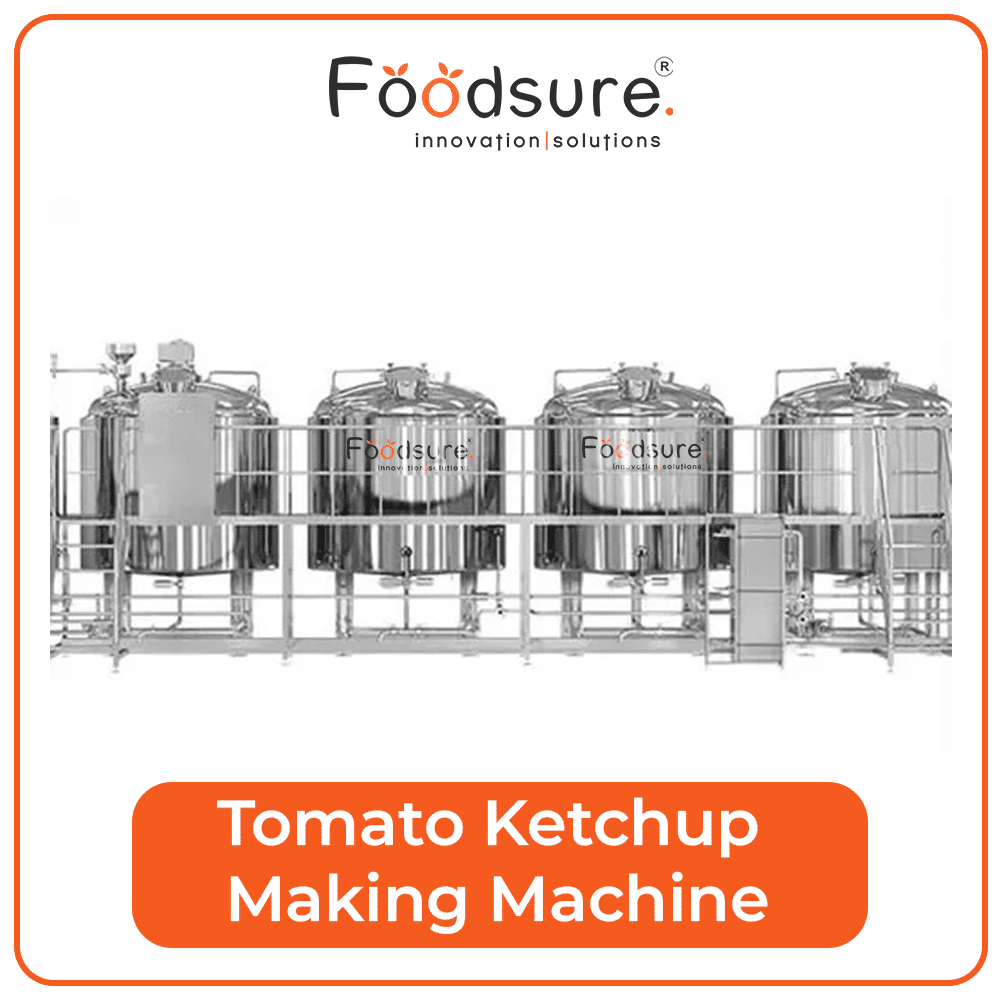

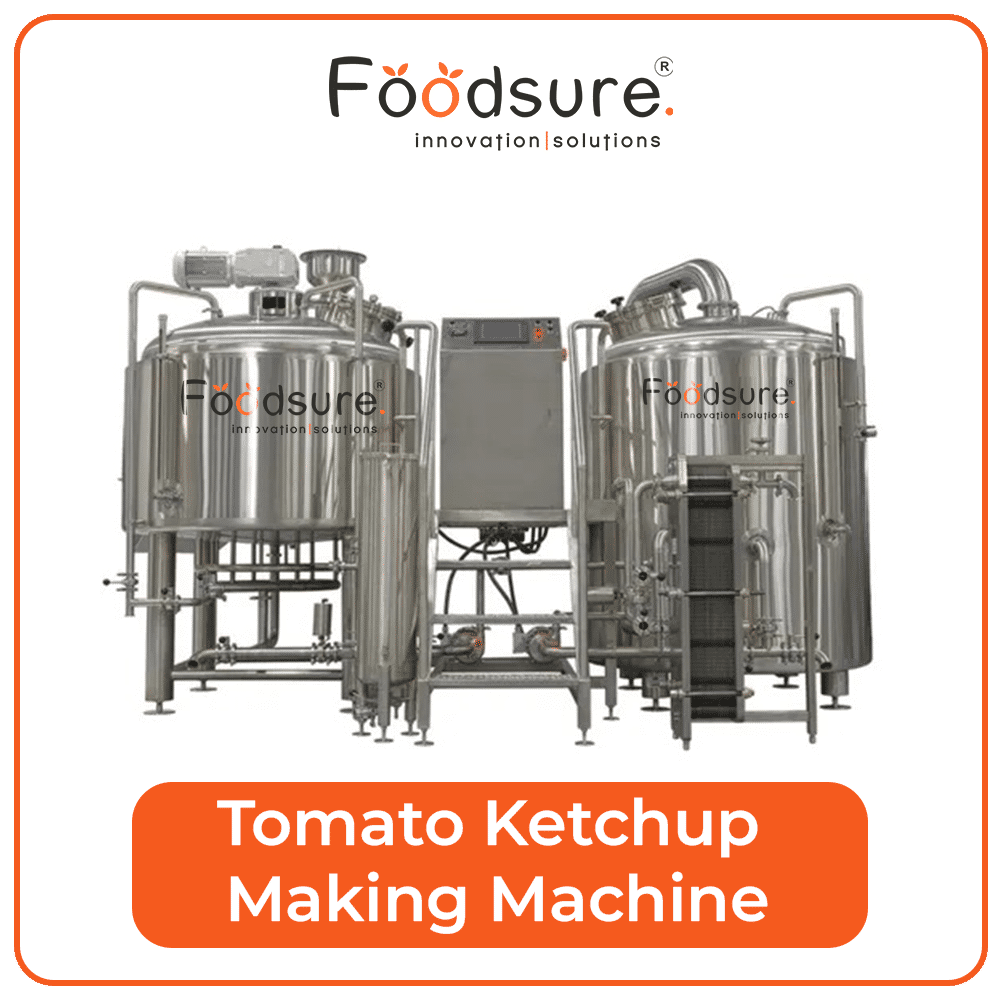

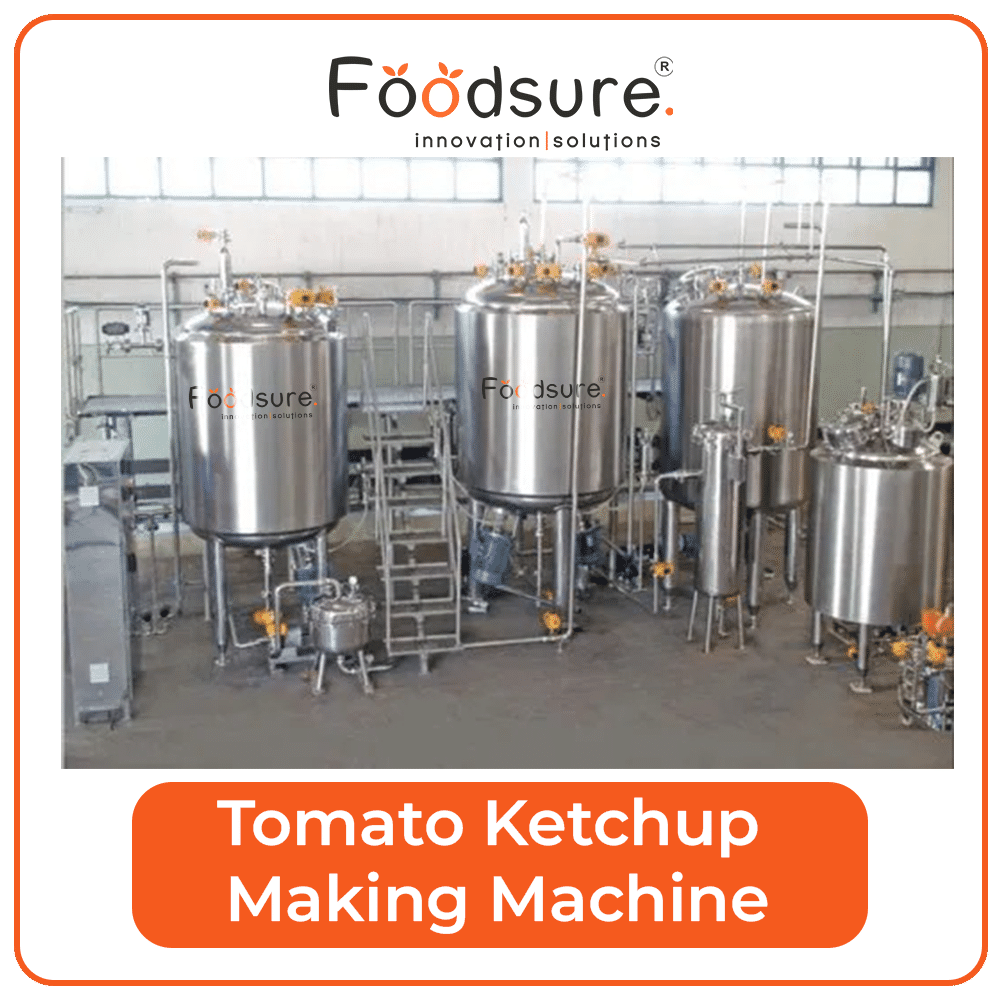

Tomato Ketchup Plant Machinery

1000000 INR/Unit

Product Details:

- Product Type Tomato Ketchup and Sauce

- General Use Industrial and Commercial

- Material Stainless Steel

- Capacity Upto 3000 Kg/day

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

X

Tomato Ketchup Plant Machinery Price And Quantity

- 1 Unit

- 1000000 INR/Unit

Tomato Ketchup Plant Machinery Product Specifications

- 420 Watt (w)

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Tomato Ketchup and Sauce

- Industrial and Commercial

- 1000 Kilograms (kg)

- Table Top

- Stainless Steel

- Yes

- Upto 3000 Kg/day

- Manual

- Yes

- 20 Watt (w)

- 1 Year

Tomato Ketchup Plant Machinery Trade Information

- New Delhi

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packing & Bubble Rap Packing

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001:2015

Product Description

Tomato Ketchup Plant Machinery

The process in the Tomato Ketchup Plant Machinery usually consists of several steps that vary according to the instructions and products required.Foodsures tomato ketchup plant is equipped with state-of-the-art machinery designed to ensure efficiency, quality, and consistency in every batch of tomato ketchup produced.

- Cleaning and cleaning: Wash the tomatoes to remove damaged or damaged parts . After damage , it should be cleaned to remove any dirt or debris .

- Peeling and seeding: After boiling , transfer the tomatoes to the peeling and seeding machine . Then the resulting pulp is collected in jars.

- Mixing and cooking: Combine tomatoes with other ingredients such as salt , sugar and spices in a large bowl . Heat and stir constantly to ensure even cooking and prevent sticking .

- Packaging: Put ripe tomatoes in a container ( such as a bottle , tin can ) and close it . Containers are labelled , packaged and shipped.

- Pasteurisation: In order to ensure the safety of the product , tomato paste is pasteurised with heat for a short time . This will kill any bacteria or other organisms that may be present .

- Cooling and Storage: Pasteurized tomato paste is cooled and stored in a temperature-controlled place until it is ready to be sent to warehouses or outlets.

Process Flow Chart for Making Tomato Ketchup Plant:

- Raw Material Reception: Fresh tomatoes are received and inspected for quality.

- Cleaning and Sorting: The tomatoes are thoroughly cleaned to remove dirt and debris. They are then sorted to remove any damaged or spoiled tomatoes.

- Chopping and Crushing: The cleaned tomatoes are chopped into smaller pieces and then crushed to form a pulp.

- Heating: The tomato pulp is heated to a specific temperature to facilitate the extraction of juice and to kill any harmful bacteria present.

- Straining: The heated tomato pulp is strained to remove seeds, skin, and any remaining solids, resulting in a smooth tomato puree.

- Mixing: The tomato puree is mixed with other ingredients such as sugar, vinegar, salt, and spices to achieve the desired flavor profile.

- Cooking: The mixture is cooked at high temperatures to thicken the ketchup and develop its characteristic flavor.

- Cooling: The cooked ketchup is cooled down rapidly to prevent spoilage and maintain freshness.

- Packaging: The cooled ketchup is filled into bottles or containers, sealed, and labeled.

- Quality Control: Samples of the finished product are tested for quality, including taste, texture, color, and shelf life.

- Storage: The packaged ketchup is stored in a controlled environment to maintain its quality until it is ready to be shipped to retailers or distributors.

- Distribution: The finished tomato ketchup is distributed to supermarkets, grocery stores, restaurants, and other food service establishments for sale to consumers.

Efficient Tomato Ketchup Production

Engineered for maximum productivity, this automated plant machinery streamlines the process of ketchup production. The stainless steel build ensures sanitation and longevity, while the compact design supports easy installation and operation. With reduced energy consumption and operational noise, businesses can benefit from lower running costs and a quieter work environment.

Eco-Friendly and Cost-Effective Operations

This machinery offers a sustainable solution for ketchup manufacturers, thanks to its eco-friendly construction and lower energy consumption. The ability to process up to 3000 kg per day enables higher output without compromising environmental responsibility or operational finances. The 1-year warranty and reliable support in India further enhance peace of mind for users.

FAQs of Tomato Ketchup Plant Machinery:

Q: How does the tomato ketchup plant machinery operate automatically while maintaining manual controls?

A: The system incorporates computerized features for automation, streamlining repetitive tasks such as heating, mixing, and packaging, while allowing operators to manually control and monitor the process for precision and flexibility.Q: What is the typical process for producing tomato ketchup with this machinery?

A: Tomatoes are fed into the stainless steel machinery, where they undergo washing, chopping, cooking, mixing with ingredients, and homogenization. The machine automates most steps, enabling efficient ketchup production up to 3000 kg per day.Q: When should the machinery be serviced to ensure optimal performance?

A: Regular maintenance is recommended every six months, but you should also schedule prompt servicing in case of unusual noises, power fluctuations, or operational inconsistencies. Assistance is available throughout India.Q: Where can this tomato ketchup machinery be installed?

A: Its compact, table top installation makes it suitable for various industrial and commercial settings, including food manufacturing plants, catering facilities, and large kitchens with adequate space and electrical provisions.Q: What are the usage benefits of the stainless steel construction in this plant machinery?

A: Stainless steel is highly resistant to corrosion and easy to clean, ensuring hygienic conditions for food processing while offering durability for long-term industrial use.Q: How does the machinery contribute to lower energy consumption and eco-friendly operations?

A: With energy-efficient designoperating at just 20 Wattsit minimizes power usage, reduces operational costs, and supports eco-friendly manufacturing by lowering its carbon footprint.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Processing Machines' category

Back to top