Welcome to Foodsure!

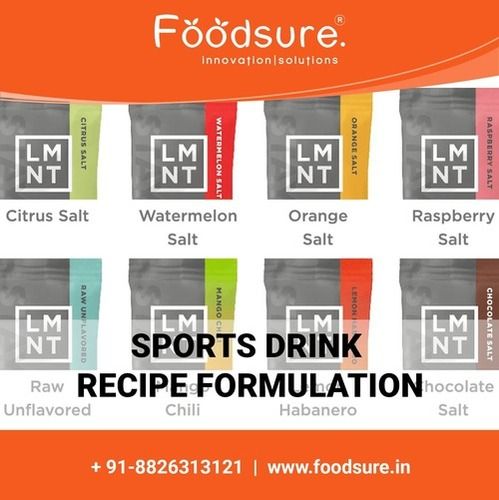

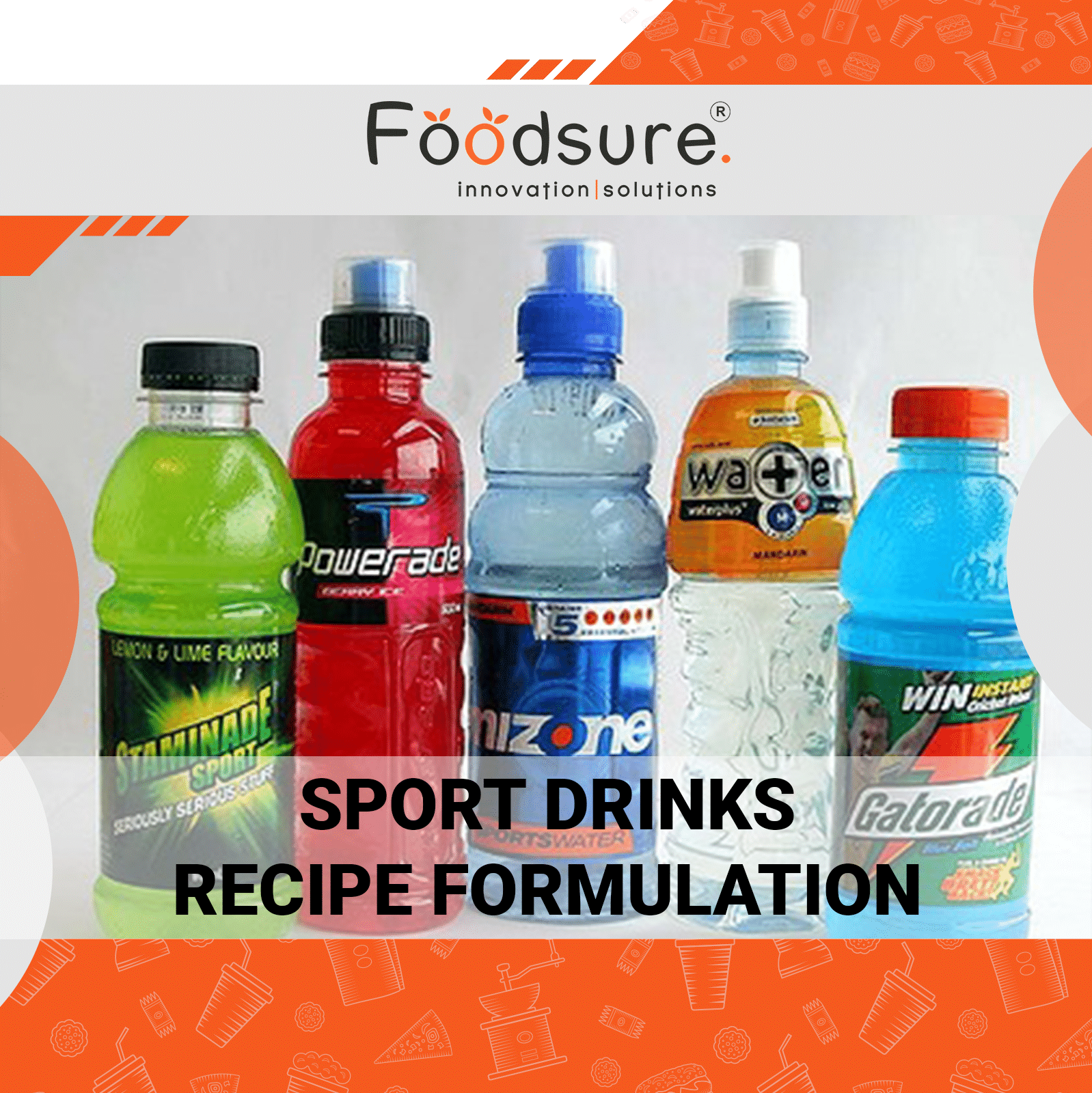

Sports Drinks Recipe Formulation

300000 INR/Unit

Product Details:

X

Sports Drinks Recipe Formulation Price And Quantity

- 1 Unit

- 300000 INR/Unit

Sports Drinks Recipe Formulation Trade Information

- New Delhi

- 10 Unit Per Month

- 25 Days

- Yes

- Free samples are available

- Pet Bottle Packaging

- All India

- ISO9001:2015

Product Description

Sports drinks are made especially to aid athletes in refueling their bodies with carbohydrates, electrolytes, and water during or after strenuous exercise. These beverages usually consist of water, electrolytes (sodium and potassium), carbohydrates (such as sugars), and occasionally vitamins or other ingredients. Sports drinks contain carbohydrates that provide you energy and electrolytes that support healthy hydration and muscular function. Sports beverages are made to be consumed prior to, during, or following physical activity in order to support athletes' recovery and performance. Lucozade, Powerade, and Gatorade are well-known brands.

Choose Foodsure as your food R&D partner for innovative solutions, tailored expertise, and meticulous attention to detail. With a dedicated team of experts and state-of-the-art facilities, we deliver superior quality, safety, and taste in every product. Collaborate with us to bring your culinary vision to life and stay ahead in the dynamic food industry.

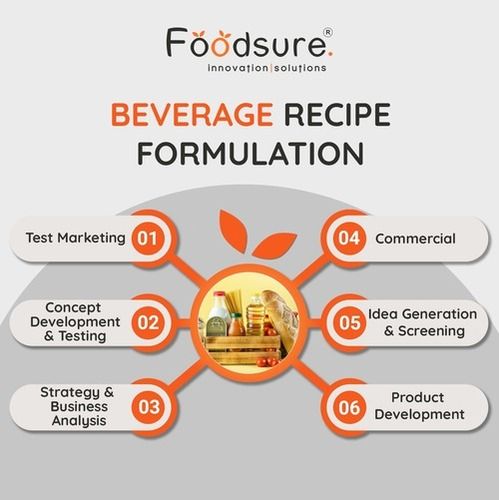

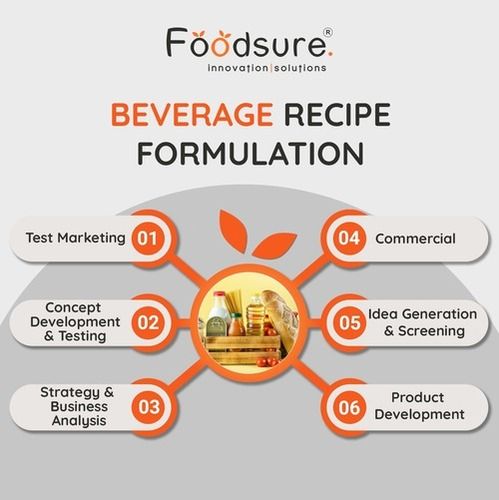

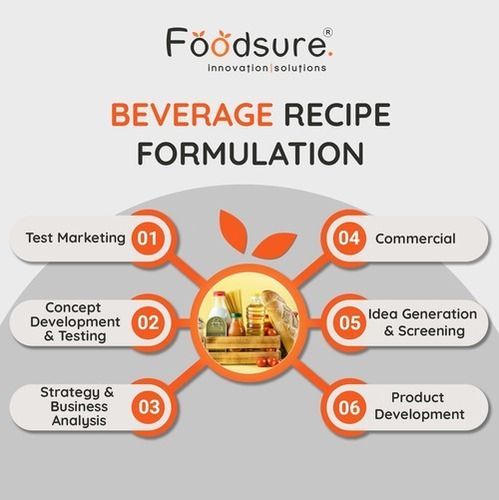

Here's an overview of our R&D process:

Market Research: We begin by conducting thorough market research to understand current trends, consumer preferences, and emerging ingredients in the functional gummies market. This helps us identify opportunities and gaps in the market that our product can address.

Concept Development: Based on our market research findings, we brainstorm ideas for the power gummies formulation. We consider factors such as target audience, desired health benefits, flavor profiles, and ingredient compatibility.

Ingredient Selection: We carefully select each ingredient based on its nutritional value, taste, texture, and functionality. Our team evaluates potential ingredients for their efficacy in delivering the desired health benefits and ensures they meet our clean label standards.

Formulation Testing: Once the ingredients are selected, we conduct small-scale formulation tests in our R&D lab. We experiment with different ingredient ratios and processing techniques to achieve the desired taste, texture, and nutritional profile.

Pilot Production: After finalizing the formulation, we move to pilot production to produce small batches of power gummies for further testing and evaluation. This allows us to assess the scalability of the recipe and identify any potential production challenges.

Sensory Evaluation: We conduct sensory evaluation tests to assess the taste, texture, aroma, and overall eating experience of the power gummies. Feedback from sensory panels helps us fine-tune the formulation to meet consumer expectations.

Nutritional Analysis: Our R&D team conducts nutritional analysis to ensure that the power gummies meet our predetermined nutritional targets and comply with regulatory requirements.

Stability Testing: We subject the power gummies to stability testing under various storage conditions to assess shelf life and ensure product quality over time.

Regulatory Compliance: Throughout the R&D process, we ensure compliance with food safety regulations and standards, including labeling requirements and ingredient restrictions.

Scale-Up and Commercialization: Once the formulation is finalized and all testing is complete, we scale up production for commercialization. Our manufacturing team follows strict protocols to maintain consistency and quality during large-scale production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Food Recipe Formulations' category

Back to top