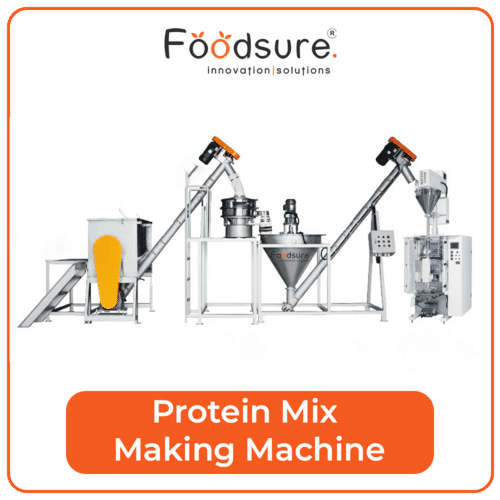

Protein Powder Processing Machine

Product Details:

- Product Type Premixes Machine

- General Use Commercial, Industrial

- Material Stainless Steel

- Type Food Processors

- Capacity upto 1000 kg Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Product Shape Other

- Click to View more

Protein Powder Processing Machine Price And Quantity

- 500000.00 INR/Unit

- 1 Unit

Protein Powder Processing Machine Product Specifications

- Food Processors

- Stainless Steel

- 1000 Kilograms (kg)

- Yes

- Premixes Machine

- 1 year

- upto 1000 kg Kg/hr

- 20 kw Watt (w)

- Commercial, Industrial

- Other

- Free Stand

- PLC Control

- Yes

- 440 V Volt (v)

- Other

Protein Powder Processing Machine Trade Information

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 15 Unit Per Day

- 15 Days

- Yes

- Free samples are available

- As per Customer

- South America, Western Europe, Central America, Asia, Middle East, Eastern Europe, North America, Africa

- All India

- ISO 9001:2015

Product Description

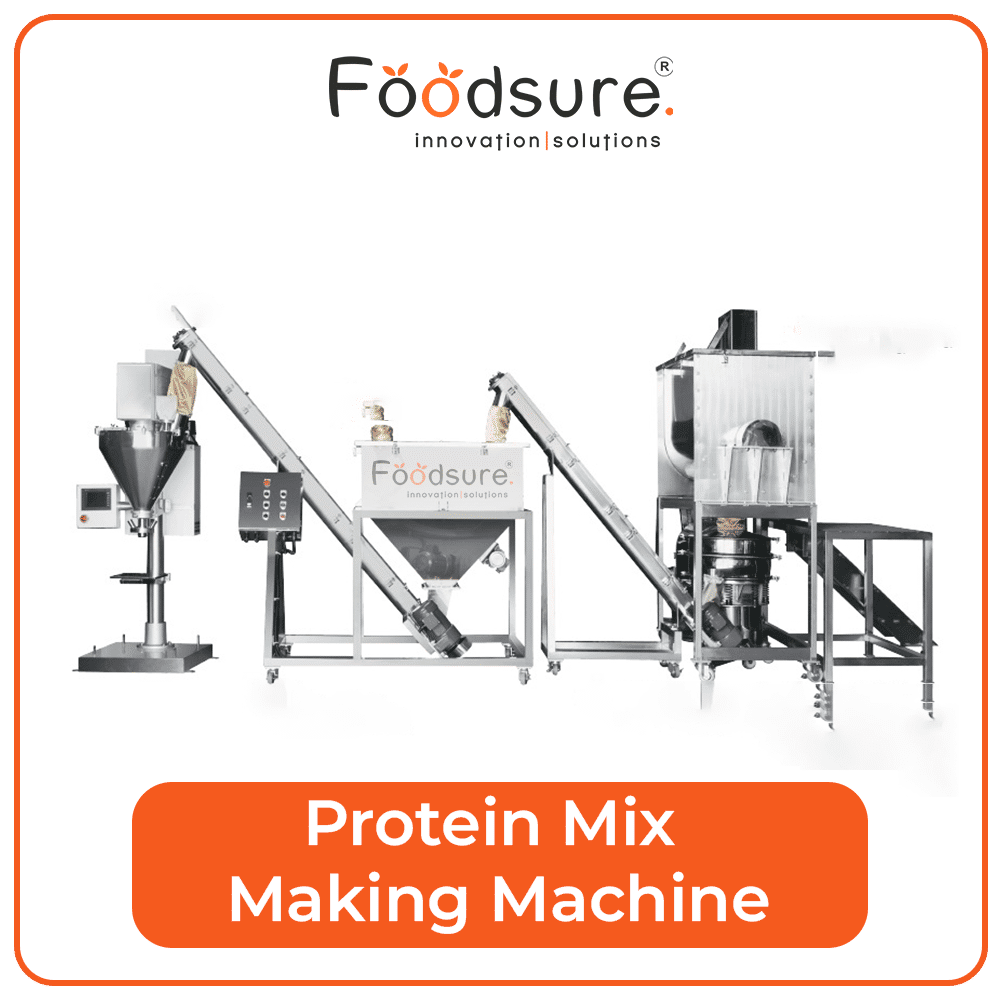

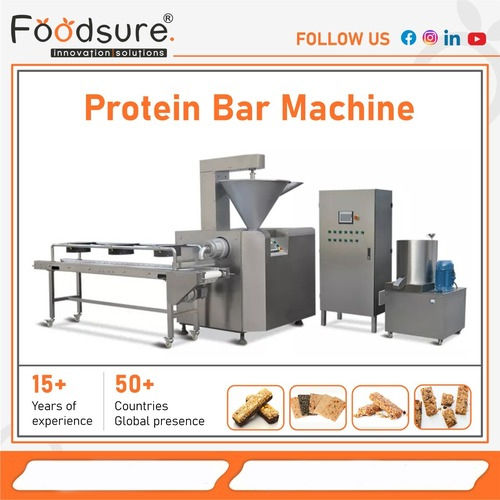

The Protein Mix Machine offered by Foodsure is a state-of-the-art solution designed to streamline the process of mixing protein-rich ingredients efficiently and effectively. This machine is engineered with precision and built to meet the demanding requirements of the food industry. Below is a detailed description of its features and capabilities:

- Robust Construction: The Protein Mix Machine is constructed using high-quality materials and components, ensuring durability and longevity even under heavy usage in industrial settings. Its sturdy frame and reinforced design make it capable of withstanding the rigors of continuous operation.

- Versatile Mixing Options: This machine offers a wide range of mixing options to accommodate various types of protein formulations. Whether it's whey protein, casein, soy protein, or pea protein, the Protein Mix Machine can handle them all with ease. It allows for precise control over mixing parameters such as speed, duration, and intensity to achieve the desired consistency and texture.

- Efficient Mixing Technology: Equipped with advanced mixing technology, this machine ensures thorough blending of protein powders and other ingredients, resulting in homogenous mixtures free from clumps or lumps. Its high-speed mixing action facilitates rapid dispersion and hydration of dry ingredients, leading to uniform distribution throughout the mixture.

- User-Friendly Interface: The Protein Mix Machine features an intuitive control panel with user-friendly interface, making it easy to operate and monitor. Operators can set custom mixing profiles, adjust parameters, and monitor the mixing process in real-time, allowing for precise control and optimization of mixing performance.

- Hygienic Design: Maintaining strict hygiene standards is essential in food processing operations, and the Protein Mix Machine is designed with cleanliness in mind. Its smooth surfaces, removable components, and easy-access design facilitate thorough cleaning and sanitation, minimizing the risk of contamination and ensuring product safety.

- Customizable Configurations: Foodsure offers customizable configurations of the Protein Mix Machine to suit specific production requirements and space constraints. Whether it's a standalone unit or integrated into a larger production line, the machine can be tailored to fit seamlessly into existing workflows and facilities.

- Compliance with Safety Standards: Safety is paramount in food processing, and the Protein Mix Machine complies with all relevant safety standards and regulations. It incorporates safety features such as emergency stop buttons, safety interlocks, and protective guards to prevent accidents and ensure operator safety.

In summary, the Protein Mix Machine from Foodsure is a reliable and efficient solution for mixing protein formulations in food processing applications. With its robust construction, versatile mixing options, efficient technology, user-friendly interface, hygienic design, customizable configurations, and compliance with safety standards, it offers unparalleled performance and reliability for protein mixing operations.

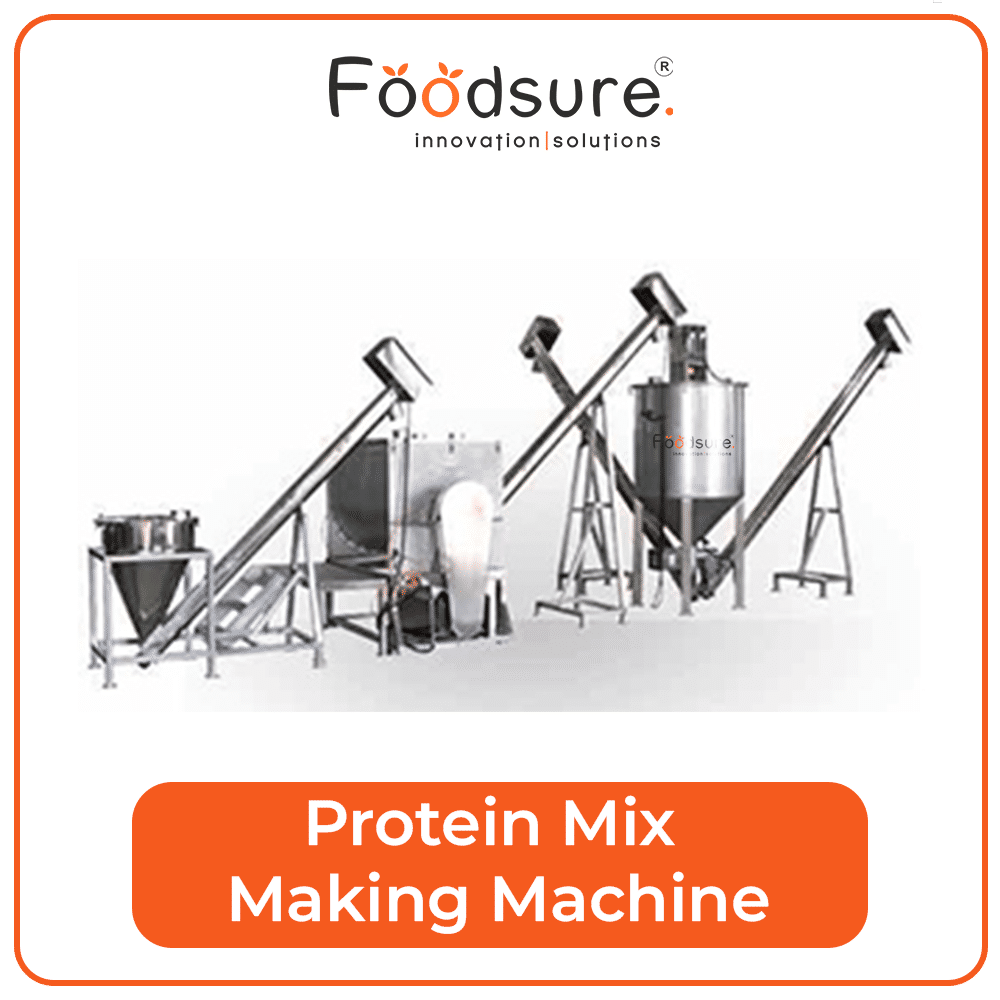

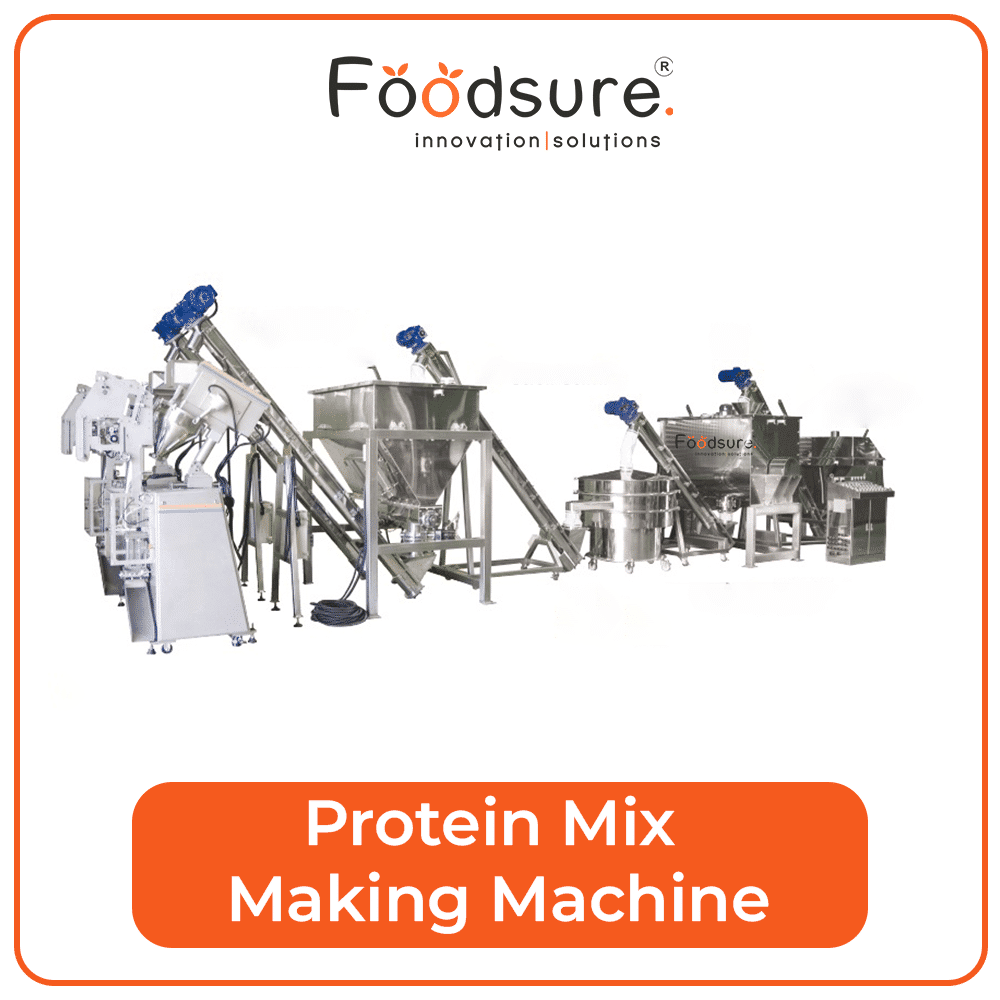

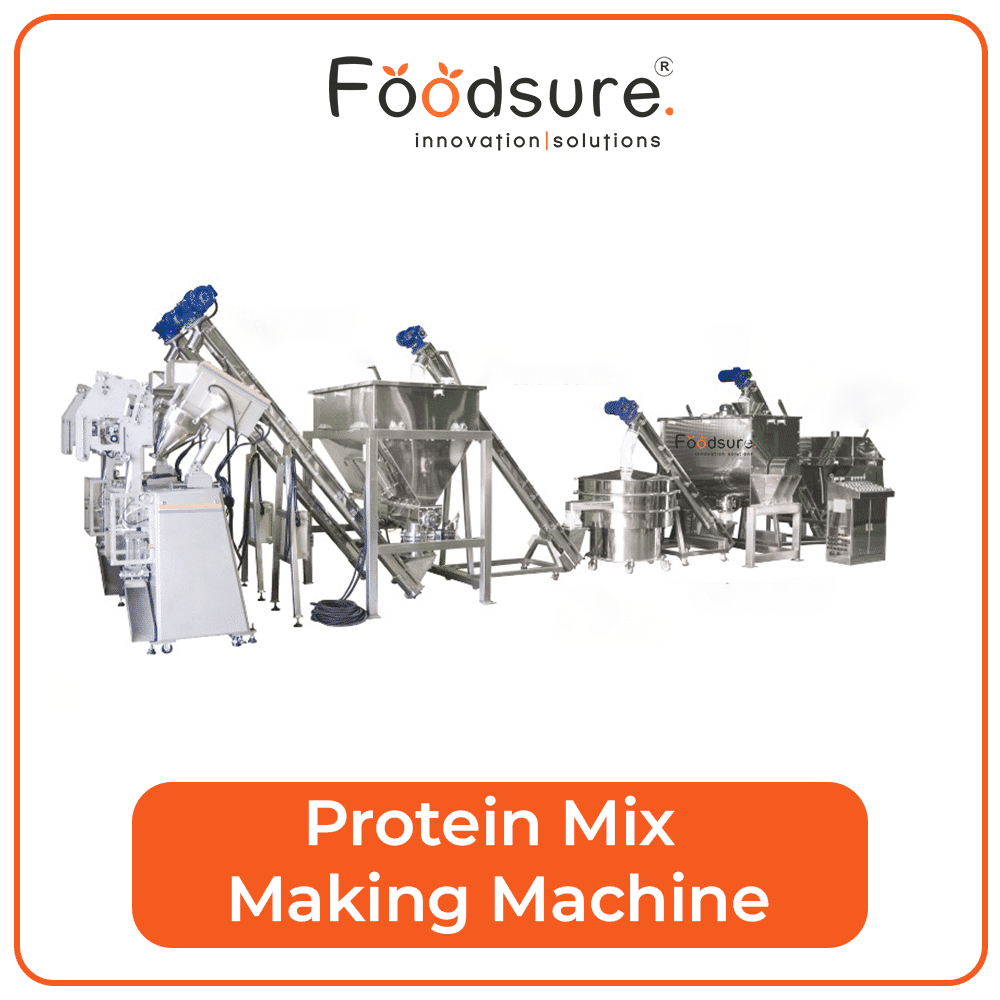

Whey protein powder premix plant and machinery is used to manufacture whey protein powder premixes, which are a popular nutritional supplement used by athletes, bodybuilders, and health-conscious individuals. The premix plant and machinery typically includes several components, such as:

- Raw material handling equipment: This includes equipment for the handling and storage of raw materials such as whey protein concentrate, flavors, sweeteners, and other additives.

- Mixing and blending equipment: This equipment is used to mix and blend the raw materials into a homogenous mixture.

- Drying equipment: The mixture is then dried using specialized drying equipment such as spray dryers, fluid bed dryers, or freeze dryers, depending on the desired product characteristics.

- Sieving and grading equipment: The dried product is then sieved and graded to ensure it meets the desired particle size and quality specifications.

- Packaging equipment: Finally, the whey protein powder premix is packaged into various sizes and formats, including jars, bags, and bulk containers.

The whey protein powder premix plant and machinery can be designed to meet specific production requirements, such as the capacity, product characteristics, and quality standards. The equipment can be fully automated, ensuring consistent product quality and reducing labor costs.

Whey protein powder premixes are a popular nutritional supplement due to their high protein content, low fat content, and ease of use. They can be used to support muscle growth, aid in post-workout recovery, and supplement a healthy diet. The manufacturing process ensures the product's safety and quality, and the premix plant and machinery can be customized to produce a range of whey protein powder products with varying flavors, textures, and nutritional profiles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+