Welcome to Foodsure!

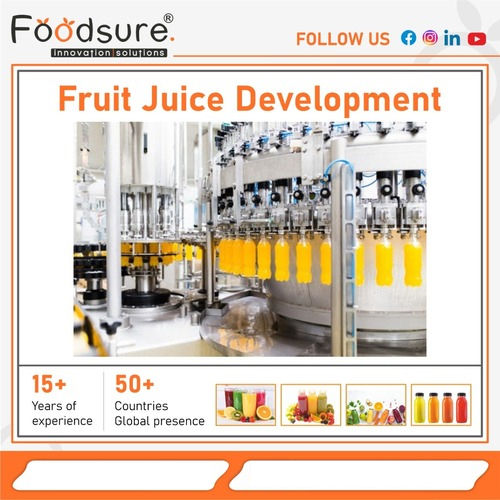

Fruit Juice Plant Setup

6000000.00 INR/Unit

Product Details:

- Product Type Fruit Juice

- General Use Industrial and Commercial

- Material Stainless Steel

- Capacity upto 3000 ltr Liter/day

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

X

Fruit Juice Plant Setup Price And Quantity

- 6000000.00 INR/Unit

- 1 Unit

Fruit Juice Plant Setup Product Specifications

- 20 Watt (w)

- Table Top

- 1 Year

- Fruit Juice

- Stainless Steel

- Yes

- Yes

- 1000 Kilograms (kg)

- Manual

- upto 3000 ltr Liter/day

- 420 Watt (w)

- Industrial and Commercial

Fruit Juice Plant Setup Trade Information

- New Delhi

- Paypal Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging; Bubble Wrap

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001;2015

Product Description

Setting up a fruit juice plant involves a series of steps to transform fresh fruits into packaged juice ready for consumption. Here™s a detailed description of the process, which typically includes the following stages:

- Selection of Fruits: The process begins with the selection of high-quality, fresh fruits. The choice of fruits depends on the desired juice flavors and the availability of the fruits.

- Cleaning and Sorting: The selected fruits are cleaned thoroughly to remove any dirt, debris, or contaminants. They are then sorted to ensure only the best quality fruits are processed.

- Extraction: The fruits are crushed and pressed to extract the juice. The method of extraction may vary based on the type of fruit.

- Filtration and Clarification: The extracted juice is filtered to remove solids and clarified to eliminate any remaining particulates, ensuring a clear and smooth juice.

- Blending: If the final product is a blend of different juices, this is the stage where the blending occurs. It™s also where any additional ingredients, like sweeteners or preservatives, are added.

- Pasteurization: The juice is then pasteurized, which involves heating it to a specific temperature to kill any bacteria and extend its shelf life.

- Packaging: After pasteurization, the juice is packaged in bottles, cartons, or pouches. The packaging is designed to maintain the quality and freshness of the juice.

- Quality Control: Throughout the process, quality control checks are performed to ensure the juice meets all safety and quality standards.

- Storage and Distribution: The packaged juice is stored in a controlled environment until it™s distributed to retailers or directly to consumers.

Choosing Foodure for setting up a fruit juice plant can be beneficial for several reasons:

- Innovative Solutions: Foodure may offer innovative processing solutions that enhance efficiency and product quality.

- Sustainability: They might prioritize sustainable practices, reducing the environmental impact of juice production.

- Customization: Foodure could provide customizable plant setups that cater to specific production needs and scales.

- Support and Training: They may offer comprehensive support and training, ensuring smooth operation and maintenance of the plant.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

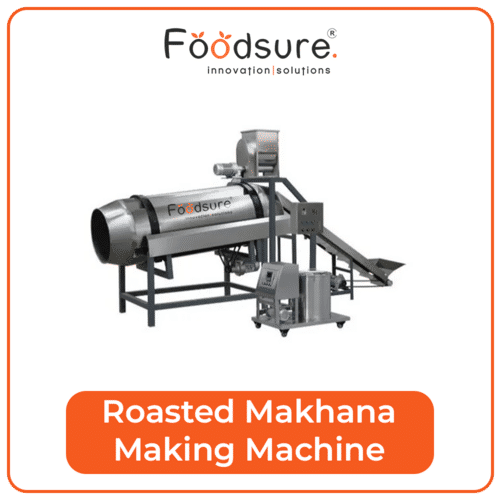

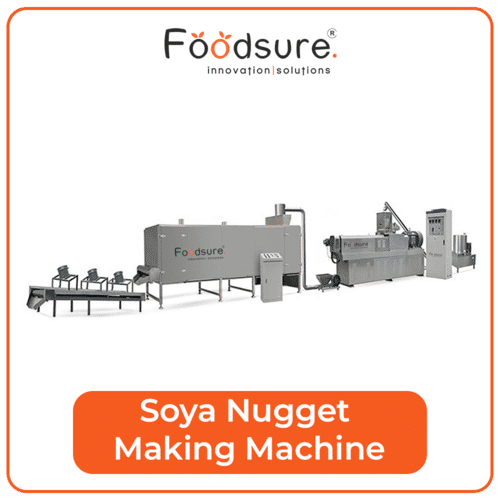

Other Products in 'Processing Machines' category

Back to top