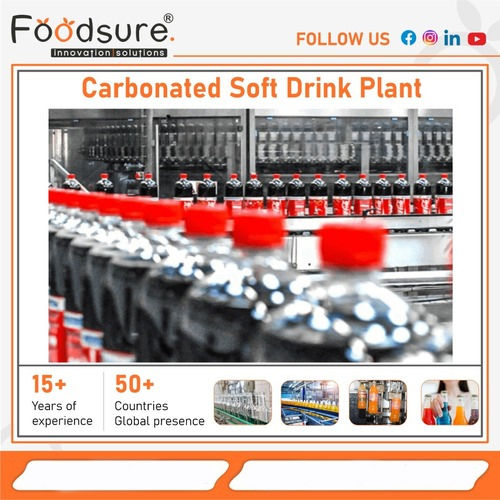

Carbonated Soft Drink Plant

Product Details:

- Product Type Carbonated Soft Drink

- General Use Industrial and Commercial

- Capacity upto 3000 ltr Liter/day

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Control System Manual

- Click to View more

Carbonated Soft Drink Plant Price And Quantity

- 1 Unit

- 7000000.00 INR/Unit

Carbonated Soft Drink Plant Product Specifications

- upto 3000 ltr Liter/day

- 1000 Kilograms (kg)

- 1 Year

- Yes

- 420 Watt (w)

- 20 Watt (w)

- Manual

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Table Top

- Industrial and Commercial

- Yes

- Carbonated Soft Drink

Carbonated Soft Drink Plant Trade Information

- New Delhi

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging, Bubble Wrap Packaging

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001:2015

Product Description

A carbonate soft drink processing plant typically involves several steps to produce a final product that is safe, consistent, and of high quality.

This type of plant is designed and built by a single vendor, who provides all the necessary equipment and resources to set up a fully operational plant. The plant is delivered as a complete package and is ready to use upon installation.

These are just a few examples of the types of carbonate soft drink processing plants available. Each type of plant has its advantages and disadvantages, and the choice of plant type will depend on the specific production requirements and budget of the soft drink manufacturerThese are just a few examples of the types of carbonate soft drink processing plants available. Each type of plant has its advantages and disadvantages, and the choice of plant type will depend on the specific production requirements and budget of the soft drink manufacturer

List of Machine-

Batch Processing Plant:This is a small-scale plant suitable for producing a limited quantity of soft drinks. The plant consists of manual or semi-automatic equipment, and the production process is done in batches.

Continuous Processing Plant:This type of plant is suitable for producing large quantities of soft drinks. The plant uses fully automated equipment that operates continuously, with minimal manual intervention.

Carbon Dioxide Recovery Plant: This type of plant is used to recover and recycle carbon dioxide from the fermentation process that occurs during soft drink production. The plant can be used to reduce the carbon dioxide consumption and save costs.

Co-Packing Plant: This is a plant that offers co-packing services to soft drink manufacturers. The plant provides the necessary equipment and resources to produce soft drinks on behalf of other companies.

Modular Processing Plant: This is a pre-fabricated plant that can be assembled on-site. The plant comes with pre-built modules that are easy to install, and the plant can be customized to suit specific production needs.

- The carbonate soft drink processing plant market is driven by the increasing demand for carbonated soft drinks worldwide. According to a report by ResearchAndMarkets.com, the global carbonated soft drinks market size was valued at USD 392.6 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2028. This growth is attributed to the increasing population, urbanization, and changing lifestyles, which have led to a rise in demand for convenience foods and beverages.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+