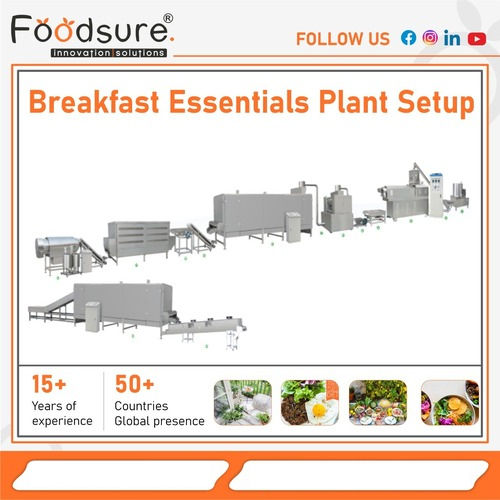

Breakfast Essentials Plant Setup Consultant

Product Details:

Breakfast Essentials Plant Setup Consultant Price And Quantity

- 1 Unit

- 200000 INR/Unit

Breakfast Essentials Plant Setup Consultant Trade Information

- New Delhi

- 10 Unit Per Month

- 30 Days

- Free samples are available

- As Per Customer

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001:2015

Product Description

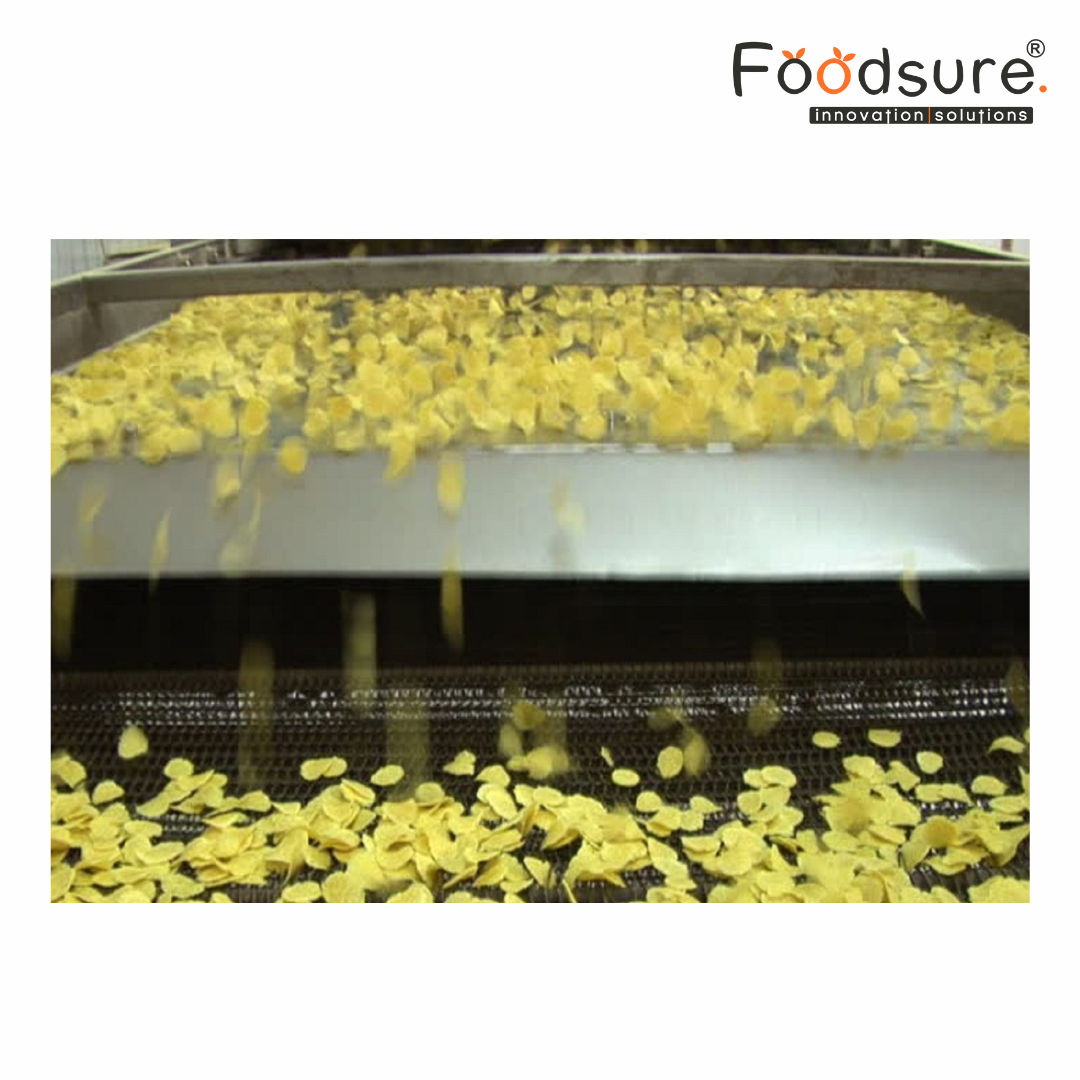

As the demand for healthy and convenient breakfast options continues to rise, the need for efficient and well-designed breakfast essentials plants becomes paramount. Breakfast essentials encompass a wide range of products, including cereals, granola bars, oatmeal, and various beverages. To meet this demand, companies require expert guidance in setting up their manufacturing plants to ensure optimal efficiency, quality control, and adherence to regulatory standards. This is where a Breakfast Essentials Plant Setup Consultant comes in.

Role and Responsibilities:

A Breakfast Essentials Plant Setup Consultant is responsible for guiding companies through the process of planning, designing, and implementing their manufacturing facilities for breakfast essentials. Their primary role is to ensure that the plant layout, equipment selection, and operational procedures are optimized for maximum efficiency and product quality. Key responsibilities include:

- Initial Assessment: Conducting a thorough analysis of the company requirements, production goals, and budget constraints to develop a tailored plan for the plant setup.

- Plant Design: Collaborating with architects, engineers, and equipment suppliers to design a layout that maximizes space utilization, workflow efficiency, and safety compliance.

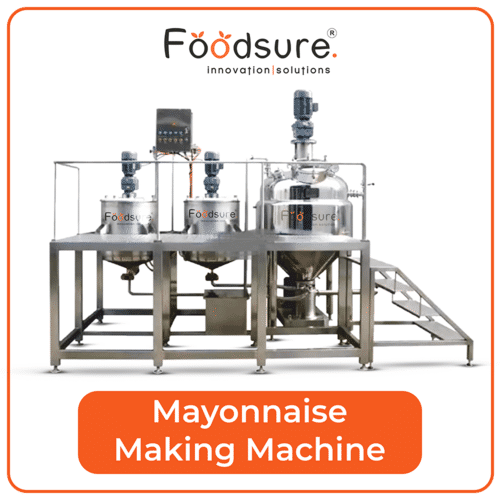

- Equipment Selection: Recommending the most suitable machinery and technology for each stage of the production process, considering factors such as production volume, product diversity, and maintenance requirements.

- Process Optimization: Streamlining production workflows, minimizing waste, and optimizing resource utilization to enhance overall productivity and reduce operational costs.

- Quality Assurance: Implementing robust quality control measures to ensure that products meet regulatory standards and consumer expectations for taste, texture, and nutritional content.

- Training and Support: Providing training programs and ongoing support to plant personnel to ensure smooth implementation of new processes and technologies.

- Continuous Improvement: Monitoring plant performance and identifying opportunities for process optimization and cost reduction through data analysis and industry best practices.

Why Choose Foodrsure?

When it comes to selecting a consultancy firm for setting up breakfast essentials plants, Foodrsure stands out for several compelling reasons:

- Expertise and Experience: Foodrsure boasts a team of seasoned professionals with extensive experience in the food manufacturing industry. Their consultants have successfully overseen numerous plant setup projects, ranging from small-scale startups to large-scale production facilities.

- Comprehensive Services: Foodrsure offers end-to-end consultancy services, covering every aspect of plant setup from initial planning and design to equipment procurement, installation, and ongoing support. This comprehensive approach ensures seamless integration of all plant components and processes.

- Customized Solutions: Foodrsure understands that each client has unique requirements and challenges. They take a personalized approach to plant setup, tailoring their solutions to align with the client's specific goals, budget, and operational constraints.

- Industry Compliance: With in-depth knowledge of regulatory requirements and industry standards, Foodrsure ensures that all plant designs and operational procedures comply with food safety regulations and quality assurance protocols.

- Innovation and Efficiency: Foodrsure stays abreast of the latest technological advancements and best practices in food manufacturing. They leverage innovative solutions and optimization strategies to enhance production efficiency, minimize waste, and maximize product quality.

- Client Satisfaction: Foodrsure is committed to delivering superior results and exceeding client expectations. Their track record of successful projects and satisfied customers speaks volumes about their dedication to excellence.

- Long-Term Partnership: Foodrsure views client relationships as long-term partnerships rather than one-off transactions. They remain engaged with clients beyond the initial setup phase, providing ongoing support and guidance to help them adapt to changing market dynamics and scale their operations sustainably.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+